Ceramic Heater Features Benefits and Customization Options

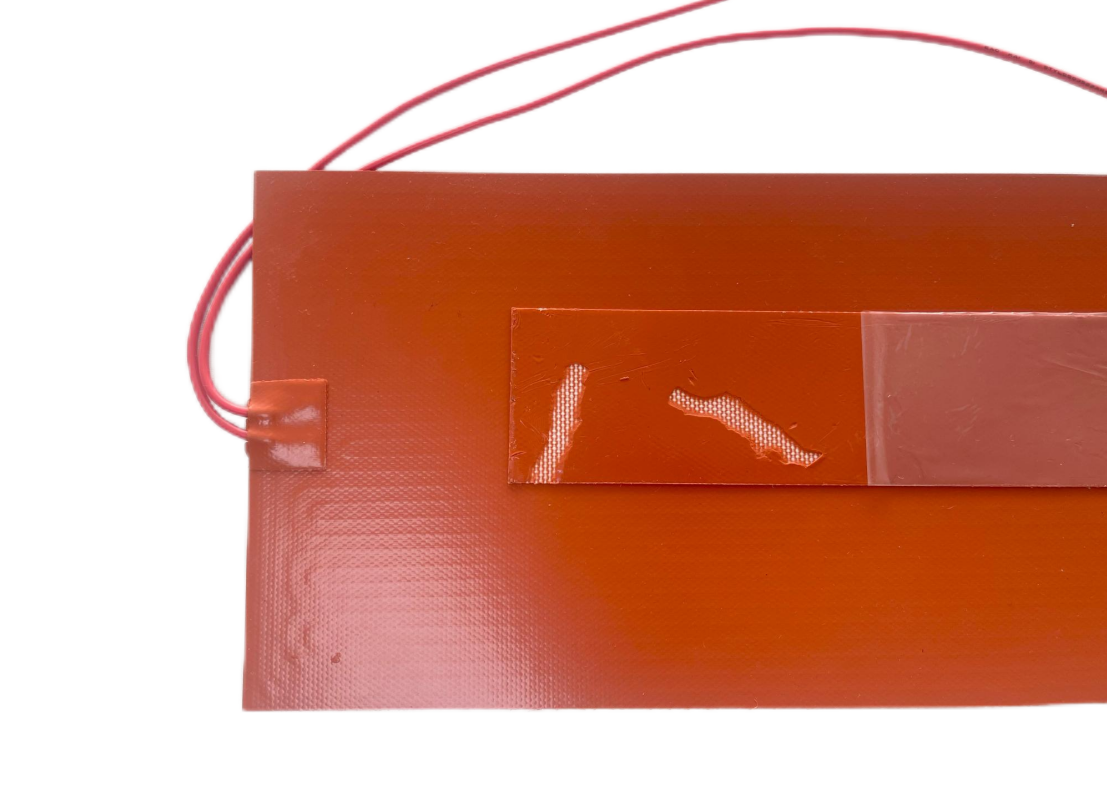

Does Your 3D Printer Need a Custom-Color Silicone Heater?

Do the Silicone Materials in Our Silicone Heaters Contain Fibers?

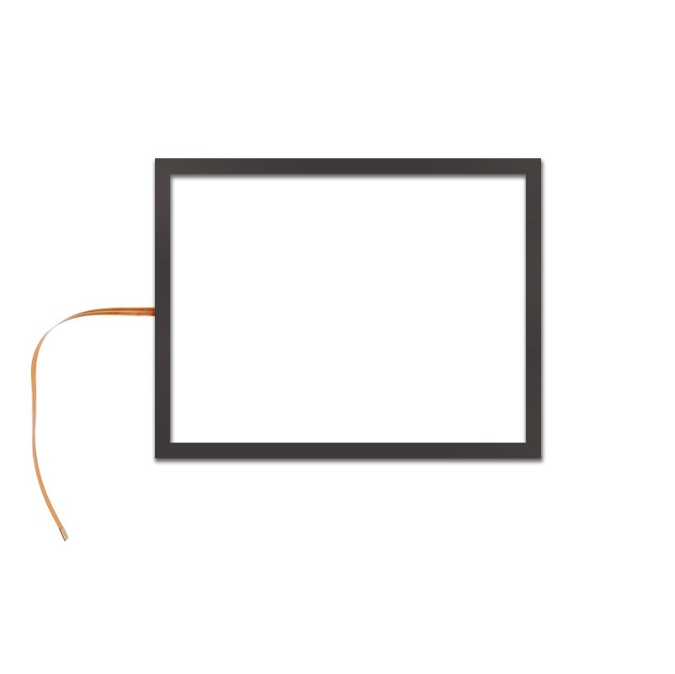

Understanding ITO Heater Thickness Impact on Resistance and Transparency

Transparent Heaters: Types, Sizes, Parameters, and Applications

When designing a heating solution, selecting the appropriate material for the heating element is critical to achieving optimal performance. The choice depends on factors such as operating temperature, efficiency, durability, cost, and specific application requirements. In this blog, we’ll explore the most commonly used materials for heaters and their respective advantages, helping you make an informed decision tailored to your needs.

1. Nichrome (Nickel-Chromium) Alloys

Nichrome is a top choice for many heating applications due to its:

High electrical resistance, which allows efficient heat generation.

Oxidation resistance, ensuring longevity at elevated temperatures.

Suitability for diverse applications, from household appliances to industrial furnaces.

2. Kanthal (Iron-Chromium-Aluminum) Alloys

Known for exceptional high-temperature performance, Kanthal is ideal for:

Applications exceeding the thermal limits of Nichrome.

Industries requiring materials with excellent oxidation and corrosion resistance.

3. Ceramic

Ceramic heaters excel in scenarios requiring:

Rapid heating and cooling, ensuring precise temperature control.

Efficient heat transfer, particularly in localized or directional heating applications.

4. Mica

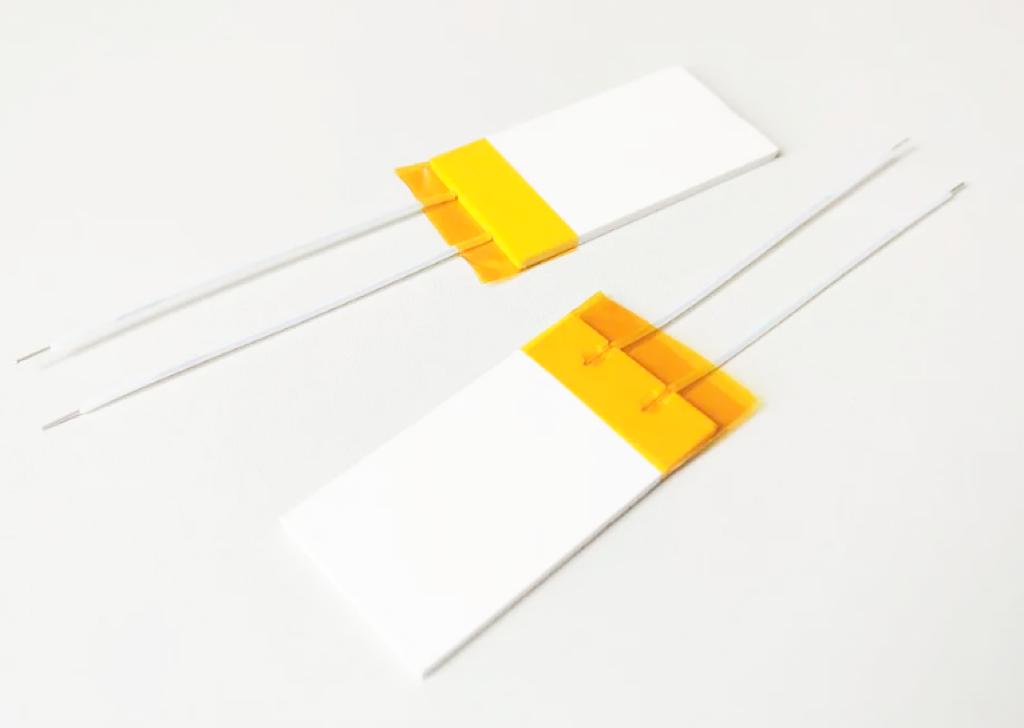

Mica is favored in compact and lightweight heating designs due to its:

Excellent electrical insulation properties.

Quick thermal response, making it suitable for applications with spatial constraints.

5. Silicon Carbide (SiC)

A standout material for high-temperature industrial uses, silicon carbide offers:

Exceptional thermal conductivity.

Ability to operate at extreme temperatures without compromising durability.

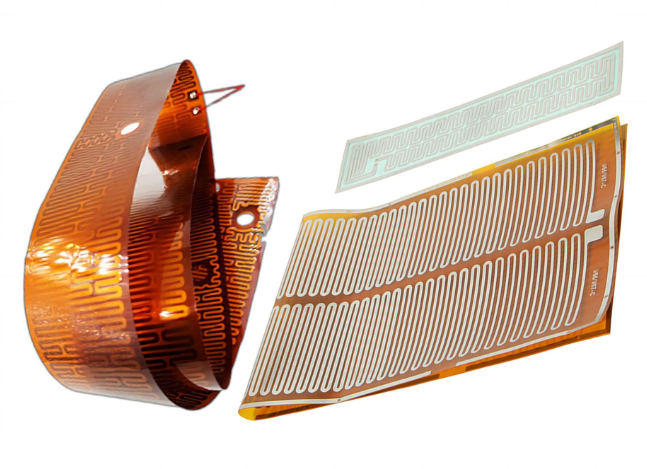

6. Carbon Fiber

Carbon fiber heaters are synonymous with speed and flexibility:

They provide rapid and uniform heating.

Ideal for applications needing lightweight and adaptable designs.

7. Copper and Aluminum

While not traditional heating elements, these metals are valuable in heat exchange systems due to their:

Superior thermal conductivity, enabling rapid heat transfer.

Use in systems like air heaters and specialized thermal exchangers.

· Temperature Range: Materials like Kanthal and Nichrome are ideal for high-temperature operations, while ceramic and carbon fiber excel in precise, controlled heating scenarios.

· Durability: For harsh environments, choose materials resistant to oxidation and corrosion, such as Kanthal or silicon carbide.

· Thermal Conductivity: Copper and aluminum ensure efficient heat transfer for specialized needs.

· Cost Efficiency: Balancing performance with budget is essential, especially for large-scale applications.

· Weight and Size: For compact systems, lightweight materials like mica and carbon fiber are optimal.

1. Household Appliances: Nichrome and mica are often used in toasters, hairdryers, and similar devices due to their efficiency and safety.

2. Industrial Furnaces: Silicon carbide and Kanthal are preferred for their ability to withstand extreme temperatures.

3. Medical Equipment: Ceramic heaters provide precision, ensuring controlled heating in sensitive environments.

4. Automotive and Aerospace: Carbon fiber heaters are ideal for their lightweight nature and rapid heating capabilities.

There is no one-size-fits-all material for heaters. The "best" choice depends entirely on your specific application requirements and environmental factors. By understanding the strengths of each material, you can tailor your heating solution for maximum performance and efficiency.

For complex or unique needs, consulting a materials expert or heating system specialist is highly recommended to ensure the best possible outcome.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.