Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

In the midst of the energy transition, energy storage batteries play a pivotal role. However, the challenge of low temperatures cannot be overlooked, as it can significantly affect battery performance. This article delves into the application of Polyimide Heater in energy storage batteries, highlighting its advantages and showcasing its remarkable effectiveness in improving battery performance and ensuring operational stability through a real-world case study.

Energy storage batteries face a significant challenge during the cold winter months: the slowing of chemical reactions due to low temperatures. This not only affects the battery's discharge efficiency but can also shorten its lifespan. The Polyimide Heater offers an effective solution to ensure stable battery performance in low-temperature environments.

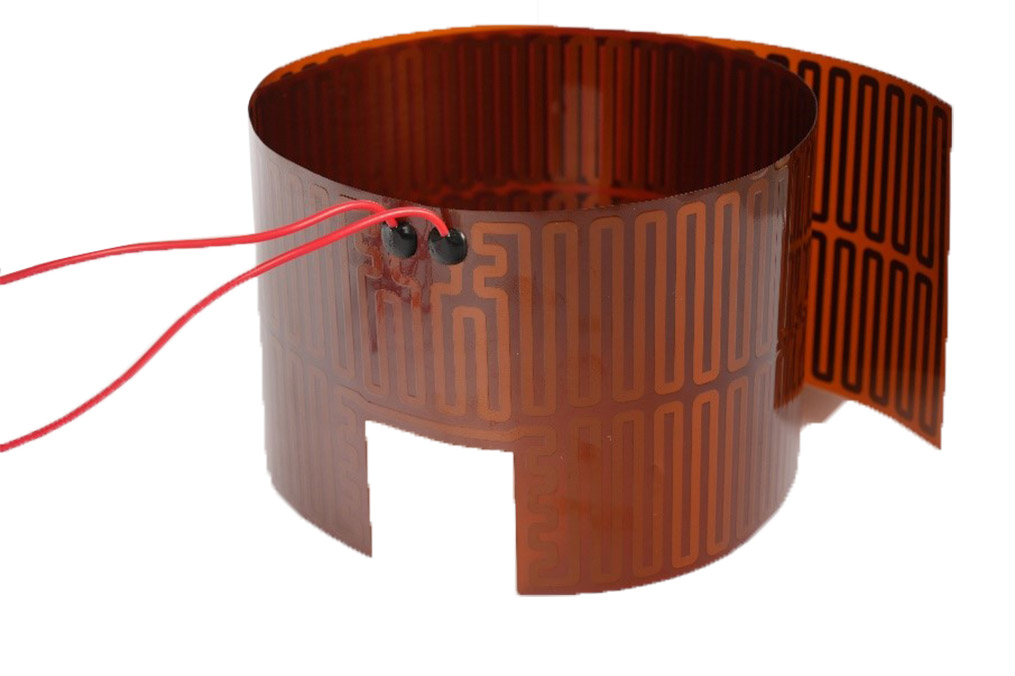

What Are the Advantages of Polyimide Heater? Polyimide Heater, as an advanced battery heating technology, boasts several key benefits:

Rapid Heating: Its superior thermal conductivity quickly raises the battery's temperature to the optimal working level, reducing performance loss due to cold.

High-Temperature Resistance: Polyimide Heater can operate stably at temperatures up to 300°C, adapting to the extreme temperature requirements of energy storage batteries.

Design Flexibility: Its thin and flexible design easily accommodates the complex internal space of batteries without impacting the overall design.

Durability: Excellent chemical stability and corrosion resistance ensure the heater's reliability and low maintenance costs over its long lifespan.

HRX Heaters have a case study highlights how a Northern European power station successfully combated winter's chill to maintain its energy supply.

Background:

A large-scale energy storage power station in Northern Europe faced a significant challenge due to its location, with temperatures often dropping below -20°C in winter. This severely affected the performance of the energy storage batteries, impacting the efficiency and stability of the power supply.

Solution:

The power station implemented a battery management system integrated with Polyimide Heater. The heater automatically activates when the battery temperature falls below a set threshold, ensuring the battery operates at the best possible temperature.

Results:

The installation of Polyimide Heater led to a noticeable improvement in the performance of the energy storage batteries under low-temperature conditions. The battery's charge and discharge efficiency increased by 20%, securing the stability of the power supply. Additionally, the efficiency and durability of the Polyimide Heater helped control operational costs effectively.

In summary, Kapton Heater technology is a game-changer for energy storage batteries, especially in cold climates. It boosts efficiency and reliability, as seen in a Northern European power station where it improved performance by 20%. As the energy storage market grows, this innovation is key for a sustainable energy future. If there is any silimar project, please feel free to contact HRX Heaters.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.