Does Your 3D Printer Need a Custom-Color Silicone Heater?

Do the Silicone Materials in Our Silicone Heaters Contain Fibers?

Understanding ITO Heater Thickness Impact on Resistance and Transparency

Transparent Heaters: Types, Sizes, Parameters, and Applications

Polyimide Heater with PT100 Sensor for Precision Thermal Management

We often receive inquiries from customers asking whether the silicone materials in our silicone heaters contain fibers. The answer is YES. All of our silicone sheets used in the production of silicone heaters contains fibers.

Types of Fibers in Silicone Sheet

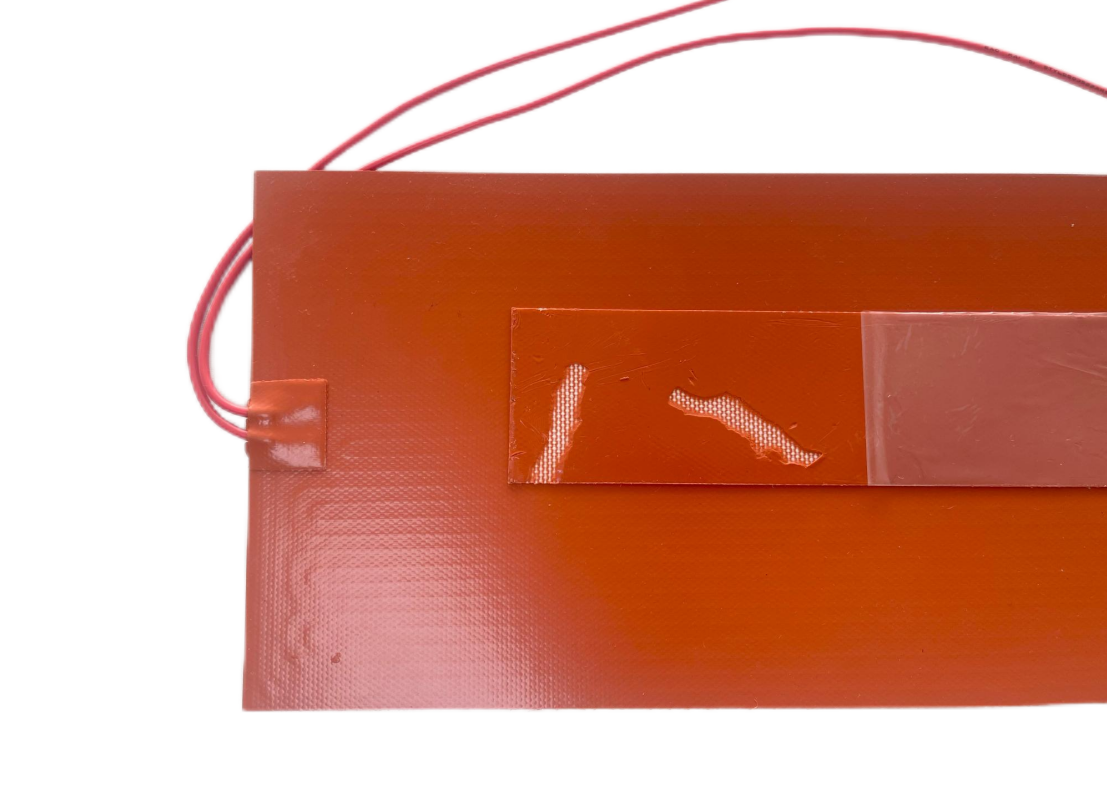

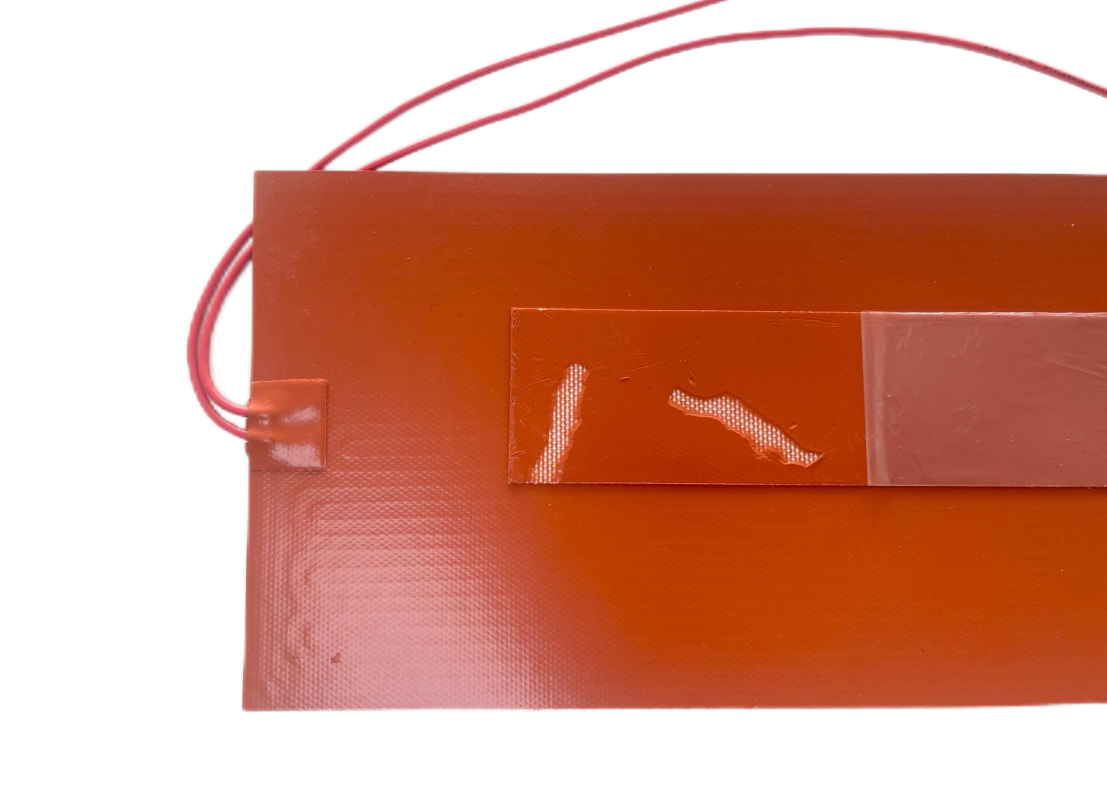

There are two main types of fibers in our silicone sheets - coarse and fine. In the past, fine - textured fibers were also used. However, we've found that they are prone to cracking under high pressure. As a result, we've essentially phased out the use of fine - textured fibers in our production, and currently, our products mainly feature coarse - textured fibers (as shown in the picture).

The Role of Fibers in Silicone Heaters

1. Enhancing Mechanical Strength

Fibers play a crucial role in strengthening the mechanical properties of silicone heaters. Silicone, on its own, has relatively limited strength. By incorporating fibers, the overall strength of the silicone heater is significantly enhanced. For example, during the normal use of a silicone heater, it may be subject to various mechanical forces such as stretching and bending. Fibers can effectively prevent the heater from breaking or deforming under these forces, thereby extending its service life. They also increase the heater's resistance to tearing, which is particularly important in industrial applications where the heater might be moved or adjusted frequently.

2. Improving Heat Conductivity

Certain fibers, like glass fiber, possess good heat - conducting properties. When added to silicone, they create a network of heat - conducting channels within the silicone matrix. This network allows heat to be transferred more efficiently and evenly throughout the heater. In a silicone heater used for heating a large surface area, such as in industrial drying applications, the presence of fibers ensures that the heat is distributed uniformly, reducing the occurrence of hot spots and cold spots. This not only improves the heating performance but also helps to save energy by ensuring that the heating process is more efficient.

3. Boosting Thermal Stability

Fibers contribute to the thermal stability of silicone heaters. When integrated into the silicone material, they raise the temperature threshold that the heater can withstand. In applications where the silicone heater needs to operate at high temperatures for extended periods, like in some manufacturing processes, the fibers prevent the silicone from softening, degrading, or losing its shape due to heat. This thermal stability is essential for maintaining the reliability and safety of the heater under harsh operating conditions.

Real-World Applications Where Fiber Makes the Difference

Food Processing - Handles daily washdowns without degradation

Packaging Machines - Survives constant flexing and compression

Medical Equipment - Maintains precision at critical temperatures

Aerospace - Passes vibration and altitude testing

In conclusion, the fibers in our silicone heaters are an essential component that significantly contributes to the performance and durability of the product. We are committed to providing our customers with high - quality silicone heaters that meet their specific needs, and the use of the right type of fibers is an important part of ensuring this quality.

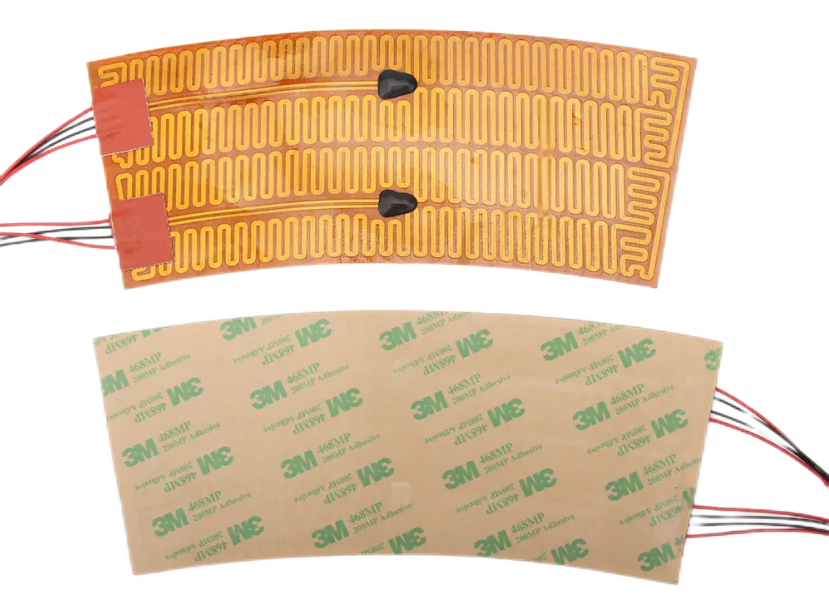

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.