The Key Differences Between Ceramic Heaters and PTC Heaters

Ceramic Heater Features Benefits and Customization Options

Does Your 3D Printer Need a Custom-Color Silicone Heater?

Do the Silicone Materials in Our Silicone Heaters Contain Fibers?

Understanding ITO Heater Thickness Impact on Resistance and Transparency

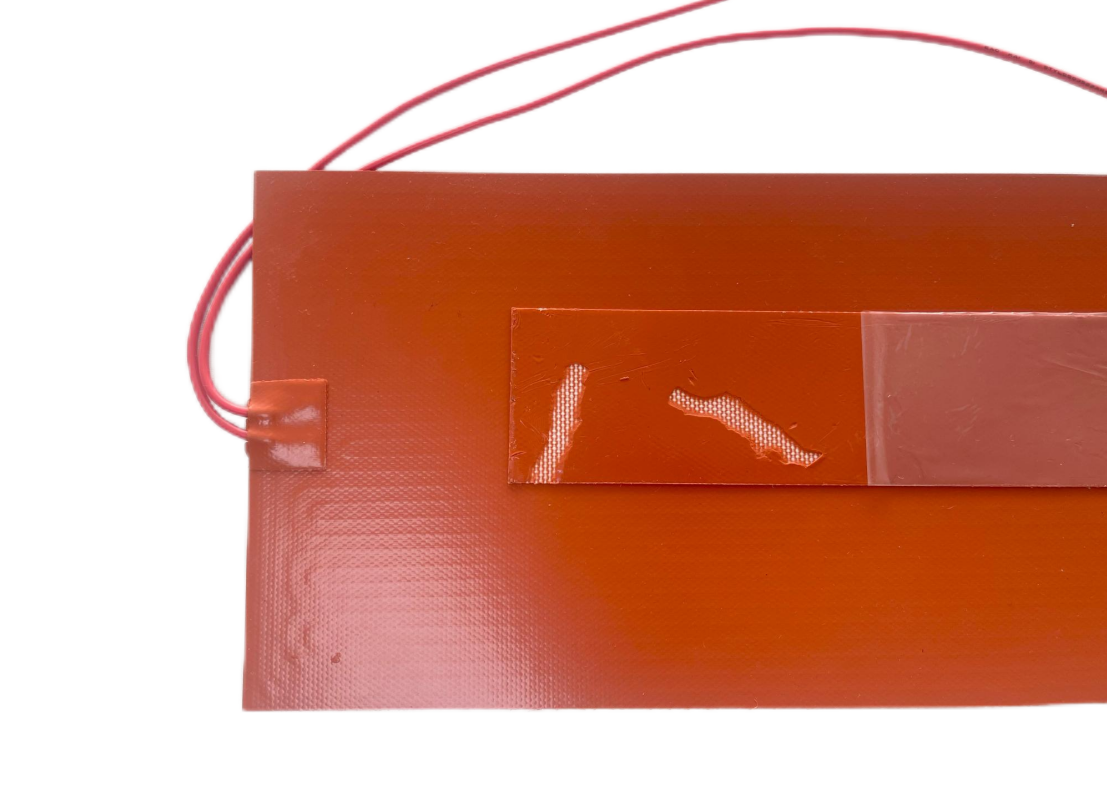

Silicone heaters have become an essential component in a variety of industries due to their flexibility, high efficiency, and ability to withstand demanding environments. Made from silicone rubber and integrated with conductive elements, these heaters offer consistent, uniform heat distribution and are customizable to suit various heating needs. In this blog post, we'll explore the diverse applications of silicone heaters and why they are an ideal solution for many industrial, commercial, and residential applications.

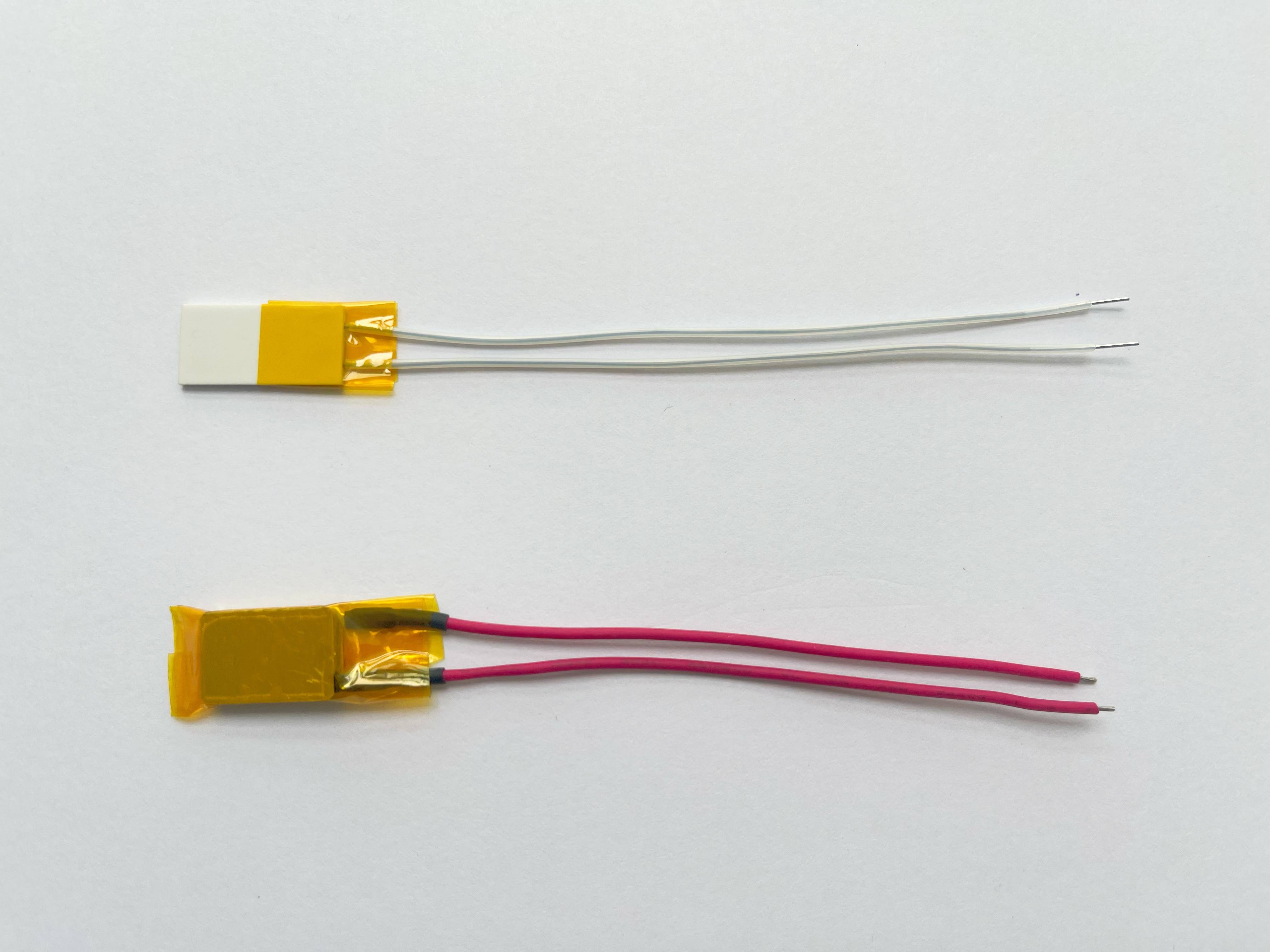

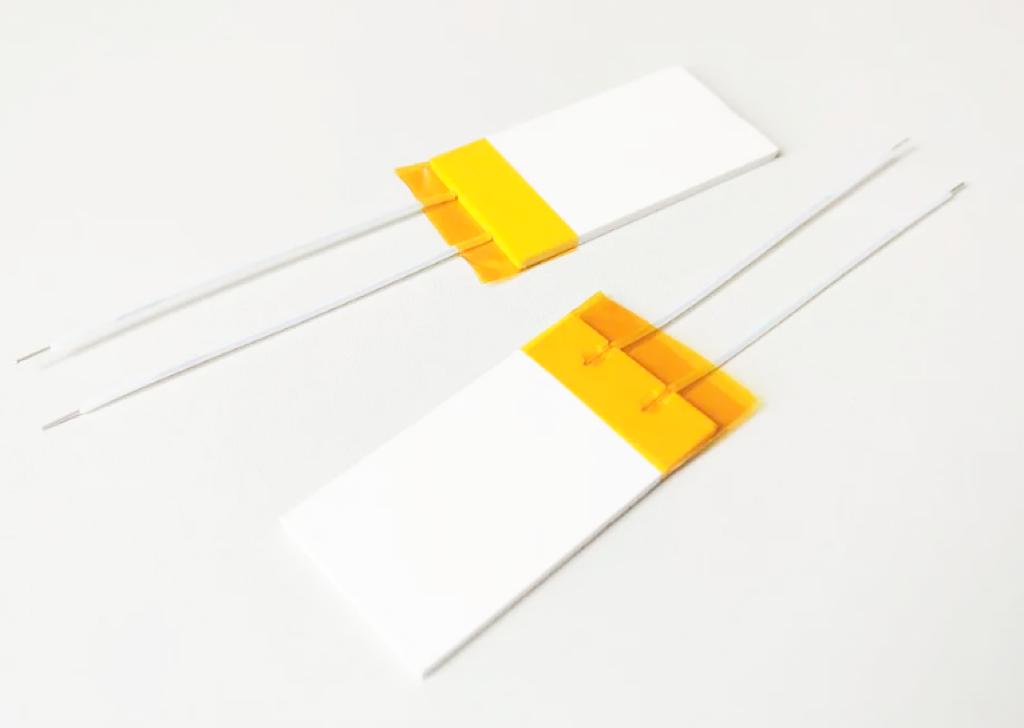

Silicone heaters are flexible heating elements made from a silicone rubber material, which is designed to provide efficient heat transfer while being resistant to extreme temperatures, moisture, and harsh chemicals. They are often used in scenarios where traditional rigid heating solutions, such as metal or ceramic heaters, would be impractical or too bulky. The flexibility of silicone allows these heaters to conform to irregular shapes, making them an ideal solution for a wide range of heating applications.

1. Industrial Processes In industries where maintaining precise and consistent temperatures is crucial, silicone heaters play a key role. These heaters are used for preheating materials, curing adhesives or coatings, drying products, and thermal bonding processes. Silicone heaters can also be used in molds and containers to maintain the optimal temperature, thus improving the quality and efficiency of production.

2. Medical Equipment Silicone heaters are widely utilized in the medical field for applications that require consistent and safe temperature control. They are commonly found in patient warming blankets, incubators for premature infants, and equipment for laboratory research. Their ability to provide gentle, even heat makes them ideal for use in sensitive medical environments, helping to regulate body temperatures or keep medical solutions and instruments within optimal temperature ranges.

3. Food and Beverage Industry The food and beverage industry benefits from silicone heaters in several ways. From keeping food warm during transport or storage to maintaining precise temperatures for melting ingredients, silicone heaters are an essential tool. They are used in food-processing lines to control temperatures during packaging and ensure the consistency of temperature-sensitive food items.

4. Aerospace and Aviation One of the more specialized uses of silicone heaters is in the aerospace industry. They are employed in aircraft and spacecraft for de-icing critical components such as wings, tail surfaces, and sensors. Silicone heaters help maintain the performance of these components in harsh weather conditions by preventing ice accumulation, which could compromise the safety and functionality of the aircraft.

5. Automotive Applications Silicone heaters are commonly used in the automotive industry for a variety of applications, such as engine preheating, battery warming, and cabin heating. They help to improve vehicle performance, particularly in cold weather, by facilitating quicker engine warm-up times, which in turn reduces wear and enhances fuel efficiency. Additionally, silicone heaters are used in heated seats and steering wheels for driver and passenger comfort.

6. Semiconductor Manufacturing In the semiconductor industry, maintaining stable temperatures is essential for producing high-quality chips. Silicone heaters are used in various stages of semiconductor manufacturing, such as wafer testing and material curing, where precise temperature control is necessary for optimal production conditions.

7. 3D Printing In the rapidly growing world of 3D printing, silicone heaters have found an important role. These heaters are integrated into 3D printers to regulate the temperature of the print bed. By ensuring a stable, consistent temperature, silicone heaters help prevent issues such as warping and adhesion failures, allowing for the production of high-quality 3D printed objects.

8. Laboratory and Testing Equipment Many scientific applications require controlled temperature environments, which silicone heaters can provide. These heaters are often used in incubators, environmental chambers, and scientific instruments to maintain a stable temperature, enabling precise experiments and tests. Their flexibility and ability to evenly distribute heat are particularly beneficial in lab settings, where small, uniform heating solutions are required.

9. Oil and Gas Industry In the oil and gas sector, preventing fluid freezing and maintaining consistent temperatures in storage tanks and pipelines are vital. Silicone heaters are used to prevent the freezing of fluids and keep them flowing, especially in cold environments. They are also used in drilling operations to ensure equipment and materials are kept at the right temperature for optimal performance.

10. Renewable Energy Systems Silicone heaters can also be integrated into renewable energy systems, such as solar panels and wind turbines. For solar panels, silicone heaters can be used to prevent the buildup of snow and ice, ensuring the panels can continue to function efficiently even in cold climates. By maintaining the temperature of critical components, these heaters help improve the overall performance of renewable energy systems.

11. Environmental Chambers In testing environments where extreme temperatures and humidity levels need to be simulated, silicone heaters are often used to create the required conditions. Whether it's for product testing or research, these heaters are able to provide precise and controlled heat within environmental chambers, ensuring accurate and repeatable results.

12. Consumer Electronics Silicone heaters also find their way into consumer electronics, particularly in devices that require localized heating. For example, in heated seats for cars or hand warmers, silicone heaters offer a compact and efficient solution. Their flexibility and low-profile design allow them to be integrated into a variety of products without adding significant bulk.

Silicone heaters are preferred in many industries due to their unique advantages:

· Flexibility: Silicone heaters can be made in a variety of shapes and sizes, conforming to the surfaces they heat. This makes them ideal for irregularly shaped components or areas where rigid heaters would be impractical.

· Even Heat Distribution: Unlike traditional heating methods, silicone heaters provide uniform heat distribution, which helps to avoid hotspots and ensures consistent performance.

· Durability: Silicone rubber is highly resistant to extreme temperatures, moisture, and chemicals, making these heaters highly durable and suitable for harsh environments.

· Customization: Silicone heaters can be easily tailored to meet specific heating needs in terms of size, shape, wattage, and voltage, providing a bespoke solution for a wide range of applications.

From industrial and medical applications to renewable energy and consumer electronics, silicone heaters are an indispensable technology in a wide range of industries. Their flexibility, durability, and customizable features make them ideal for applications that require consistent and efficient heating solutions. As industries continue to evolve and seek more efficient and versatile heating methods, silicone heaters will undoubtedly play an increasingly important role in helping to meet these challenges.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.