How Aluminium Foil Heaters Work and Where to Use Them?

How PI Graphene Heating Films Achieve "Instant Heat-up" and "Ultra-Low Energy Consumption"?

12 Safety & Longevity Guidelines Before Installation for Flexible Film Heaters

Battery Drying & Formation Equipment Heating Plate

How Flexible Heaters Achieve Consistent Medical Fluid Warming?

With advancements in industrial technology, flexible heaters have gained popularity due to their unique advantages such as flexibility, lightweight, and ease of installation. However, selecting the appropriate flexible heater for a specific project requires careful consideration of various factors to ensure it meets the specific needs of the project.

Key Factors to Consider in Choosing a Flexible Heater

Heating Requirements:

Determine the temperature range required for your project. For instance, FPC (polyimide) heaters can operate within a temperature range of 200°F to 500°F, suitable for applications requiring high-temperature heating.

Consider the uniformity and stability of heat distribution. Flexible heaters should provide even heat distribution to avoid localized overheating or cold spots.

Installation Environment:

Assess the size and shape of the installation space. Flexible heaters should be able to adapt to different installation environments, such as curved surfaces and confined spaces.

Consider the temperature and humidity conditions of the environment. Some flexible heaters feature waterproof and corrosion-resistant properties, suitable for harsh environments.

Cost-Effectiveness:

Compare the prices and performance of different types of flexible heaters. For example, polyester flexible heaters (PET heating films) may be more economical in certain applications compared to silicone heaters.

Consider the maintenance costs and replacement cycle for long-term usage.

Safety and Reliability:

Ensure that the selected flexible heater complies with relevant safety standards and regulations.

Choose heaters that have undergone rigorous testing and validation to ensure their reliability and stability.

Customization Needs:

If your project requires a specific size, shape, or power for the flexible heater, choose a supplier that offers customization services.

Consider the connectivity and scalability of the heater for future project expansions and upgrades.

Types of Flexible Heaters

FPC Heating Films (Polyimide Heaters):

Advantages: High temperature resistance (up to 395°F), excellent heat transfer capabilities, uniform heat distribution, and stability.

Applications: Aerospace, automotive, electronics, and other fields requiring high-temperature heating and stable performance.

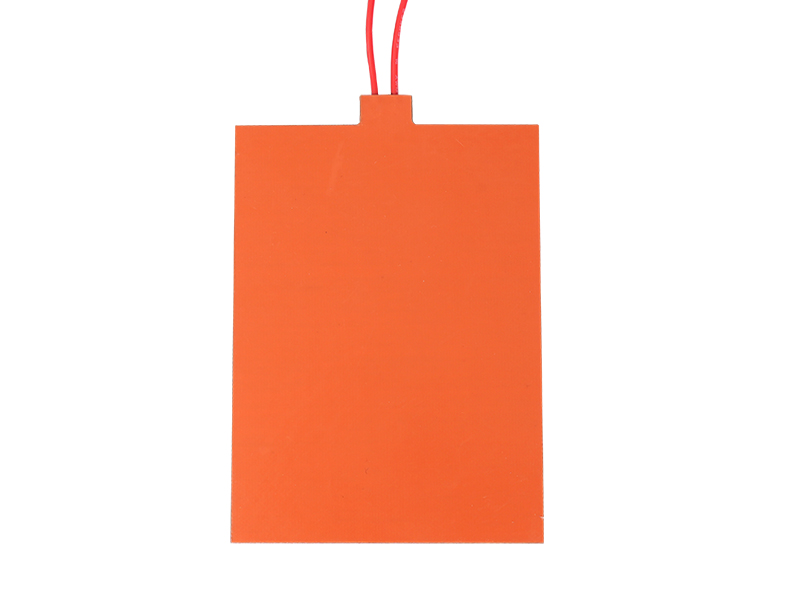

Silicone Heating Films (Silicone Heaters):

Advantages: Flexibility, easy installation and removal, and good heat transfer properties.

Applications: Medical equipment, pipeline tracing, thermal insulation, and other areas requiring flexible heating and easy maintenance.

Polyester Flexible Heaters (PET Heating Films):

Advantages: Suitable for low-temperature applications (up to 220°F), even heat transfer, and flexibility.

Applications: Food heating, de-icing, thermal insulation, and other areas requiring low-temperature heating.

Choosing the right flexible heater for your project requires comprehensive consideration of various factors, including heating requirements, installation environment, cost-effectiveness, safety and reliability, and customization needs. By understanding the different types of flexible heaters and their advantages, disadvantages, and applications, you can make a more informed decision to select the heater that best suits your project, ensuring smooth project progress and successful implementation.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.