The Key Differences Between Ceramic Heaters and PTC Heaters

Ceramic Heater Features Benefits and Customization Options

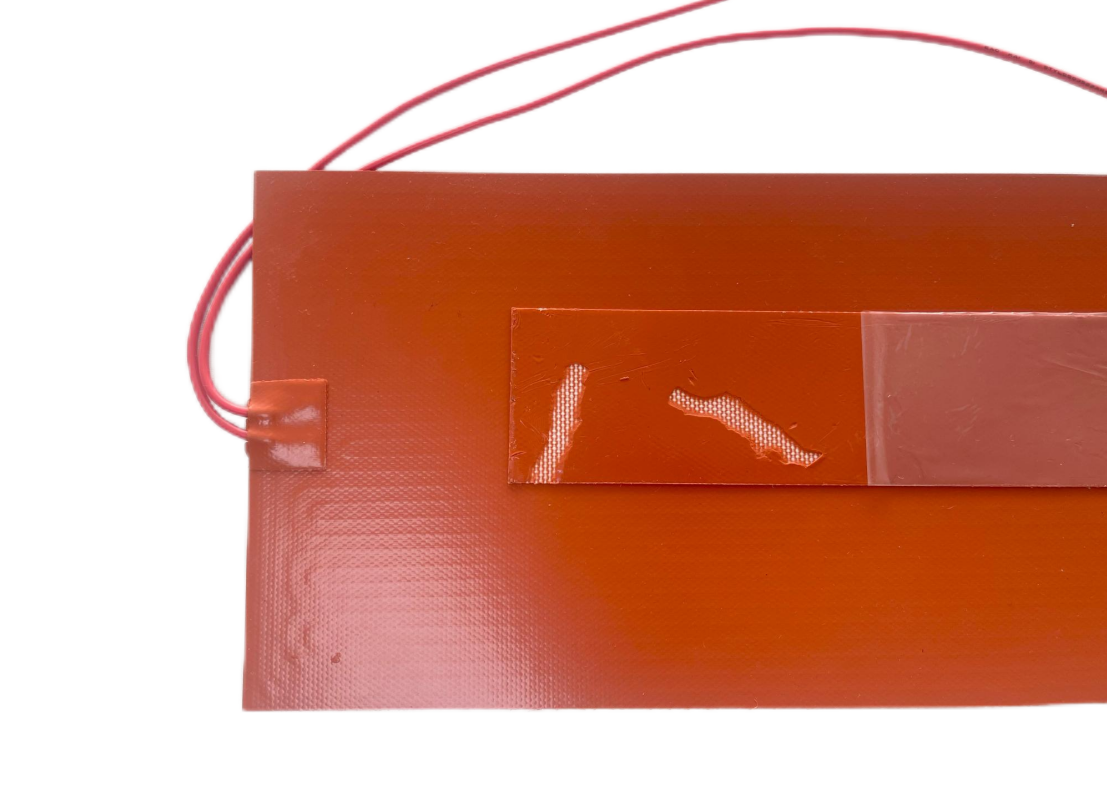

Does Your 3D Printer Need a Custom-Color Silicone Heater?

Do the Silicone Materials in Our Silicone Heaters Contain Fibers?

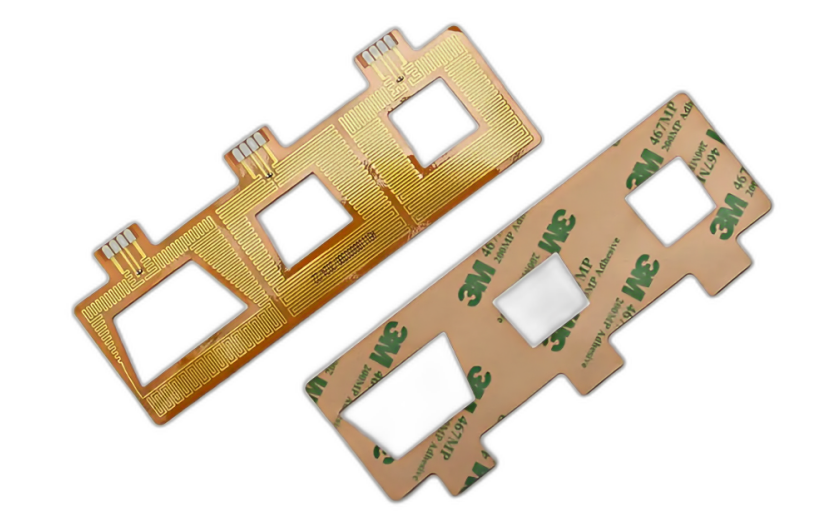

Understanding ITO Heater Thickness Impact on Resistance and Transparency

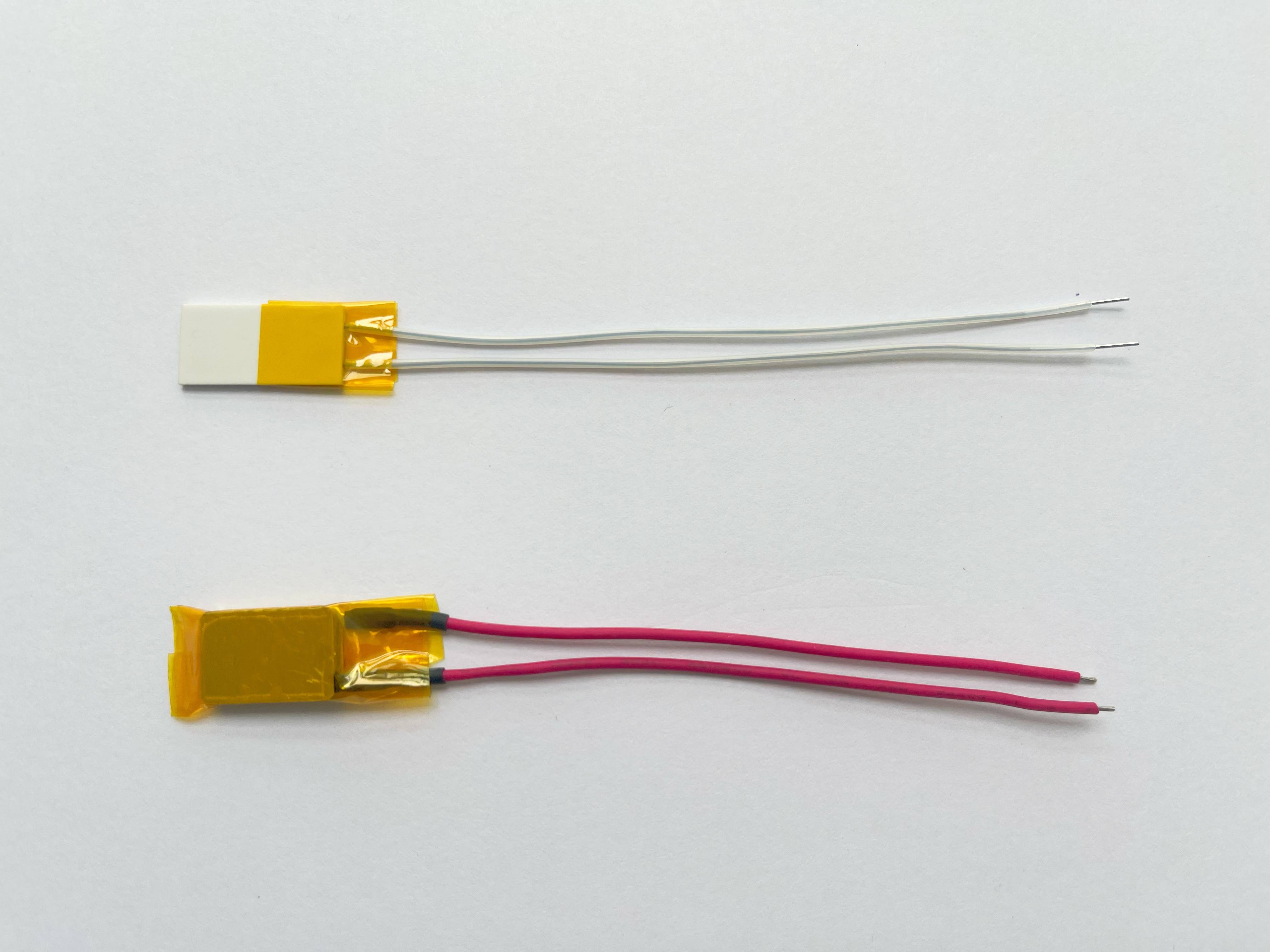

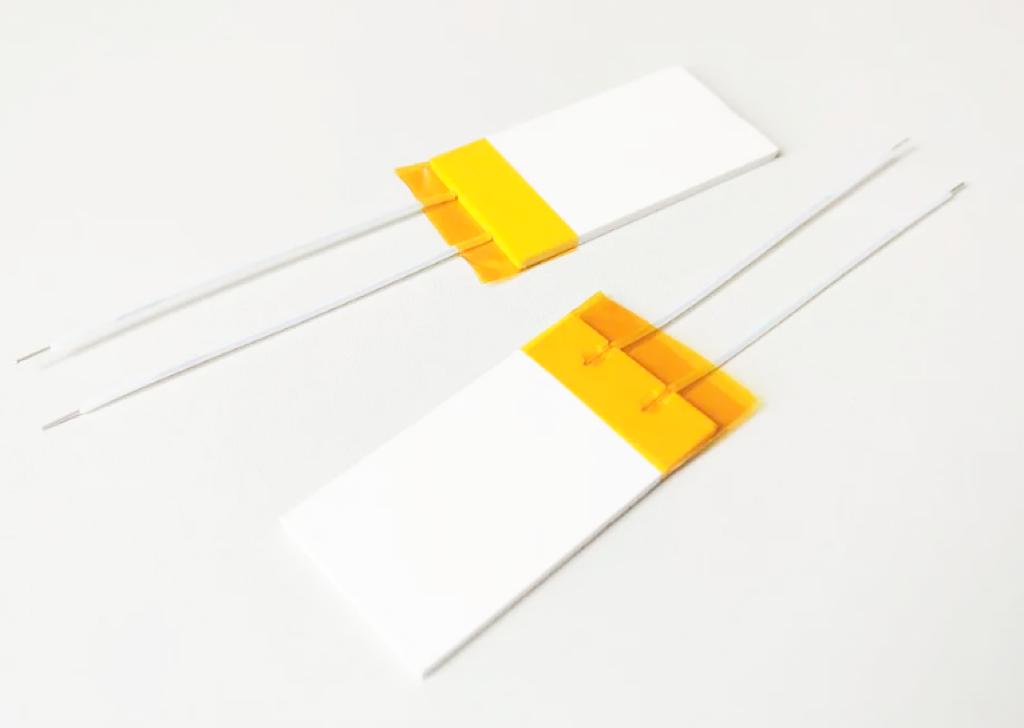

Polyimide heaters, known for their lightweight and flexible design, are widely used in applications demanding precise temperature control. The maximum temperature of these heaters depends on their design, materials, and construction. Understanding their operating limits and selecting the right heater for your application ensures safety and performance.

Polyimide heaters are typically designed to function within a standard temperature range of -40°C to 200°C (-40°F to 392°F). This range is suitable for a wide array of applications, from industrial equipment to delicate medical devices. The thermal stability and electrical insulation properties of polyimide film contribute to this impressive performance.

For demanding applications requiring greater heat resistance, advanced Polyimide heaters can be engineered to withstand extreme conditions. These specialized heaters can operate beyond 200°C (392°F) and, in some cases, handle temperatures as high as 300°C (572°F) or more.

This level of thermal capability is achieved through the use of advanced materials and precision manufacturing techniques. High-temperature Polyimide heaters are particularly valuable in industries such as aerospace, semiconductors, and energy systems, where consistent and reliable heating at elevated temperatures is critical.

When selecting a Polyimide heater, it’s essential to consider the following factors:

1. Maximum Temperature Requirement: Ensure the heater is rated to handle the operating temperature of your specific application.

2. Environmental Conditions: Factors such as humidity, pressure, or chemical exposure may impact heater performance.

3. Application Surface: Polyimide heaters are highly flexible, making them ideal for irregular surfaces, but their performance may vary depending on the material they contact.

4. Power Supply Compatibility: Verify that the heater's electrical requirements match the available power source.

Referring to the manufacturer’s specifications and guidelines is crucial to ensure the heater is used within its recommended operating limits, guaranteeing both safety and efficiency.

· Aerospace: Maintaining equipment functionality in extreme environmental conditions.

· Medical Devices: Delivering precise and controlled heating for sensitive applications.

· Semiconductor Manufacturing: Supporting intricate and precise thermal processes.

· Renewable Energy: Enhancing battery performance in cold environments.

· Automotive: Improving performance of temperature-sensitive components.

Polyimide heaters offer unparalleled flexibility and reliability across a broad temperature spectrum. Whether your application requires standard or high-temperature operation, selecting a heater tailored to your specific needs ensures optimal performance and safety. Collaborating with a trusted manufacturer can provide the expertise and custom solutions necessary for demanding environments.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.