Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

Designing custom silicone heaters is a complex process that requires careful consideration of several critical factors to ensure optimal performance and suitability for the intended application. In this blog, we will delve into the key factors of wattage, voltage, size, and shape, and how they influence the design and functionality of silicone heaters.

The wattage of a silicone heater is a fundamental factor that determines its heating power. Wattage refers to the amount of electrical power the heater consumes, and it directly influences the heater's ability to achieve and maintain desired temperatures.

Key Considerations for Wattage:

Heating Requirements:

Assess the specific heating requirements of the application, including the target temperature range and the required heating speed. For instance, applications requiring rapid heating will need higher wattage heaters.

Thermal Load:

Calculate the thermal load of the system, which includes heat losses to the environment and the thermal mass of the objects being heated. The wattage should be sufficient to overcome these losses and maintain stable temperatures.

Balance and Efficiency:

While higher wattage heaters can achieve higher temperatures more quickly, it's crucial to balance the wattage with the application's thermal requirements to avoid overheating and ensure energy efficiency.

Example:

High-Wattage Application:

Industrial machinery pre-heating might require a high-wattage heater to quickly reach operational temperatures.

Low-Wattage Application:

Medical heating pads, which need to provide gentle, controlled heat, will use lower wattage to ensure patient safety and comfort.

Voltage specifications are another critical factor in designing custom silicone heaters. The voltage must match the power supply of the application to ensure safe and efficient operation.

Key Considerations for Voltage:

Power Supply Compatibility:

Identify the available power supply voltage for the application. Common options include low-voltage (12V, 24V) for small devices and higher voltages (120V, 240V) for industrial applications.

Safety and Regulations:

Ensure that the voltage specifications comply with relevant safety standards and regulations for the specific industry and application.

Voltage Drop:

Consider the potential for voltage drop in longer power cables, which can affect heater performance. Proper wiring and power management can mitigate this issue.

Example:

Low-Voltage Application:

Battery warmers in consumer electronics often use low-voltage (12V or 24V) heaters to match the battery's voltage and ensure safe operation.

High-Voltage Application: I

ndustrial processes requiring significant heating power may utilize 240V heaters to efficiently deliver the necessary energy.

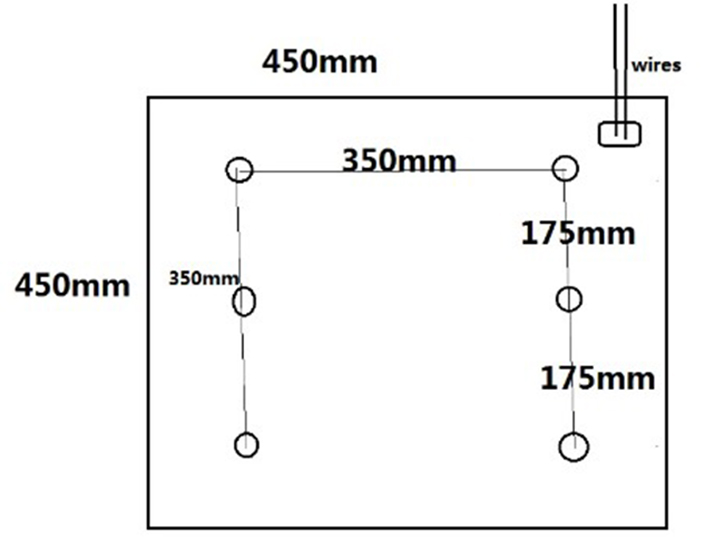

The size and shape of a silicone heater are crucial for its integration into the application. Silicone heaters are highly versatile and can be customized to fit various geometries, ensuring maximum contact and efficient heat transfer.

Key Considerations for Size and Shape:

Design Constraints:

Assess the physical space available for the heater within the application. The heater's dimensions should align with the design constraints to ensure proper fit and function.

Custom Geometries:

Silicone heaters can be cut and shaped to fit unique geometries, such as curved surfaces or irregular shapes. This flexibility allows for optimal heat distribution across the desired area.

Thickness and Flexibility:

The thickness of the heater can affect its flexibility and heat transfer efficiency. Thinner heaters offer better flexibility, while thicker heaters can provide more robust heating.

Example:

Custom Shapes:

Heaters designed for aerospace components may need to fit around complex curves and surfaces, requiring precise customization in shape and size.

Flexible Heaters:

Applications such as medical heating blankets benefit from thin, flexible heaters that conform to the body's contours.

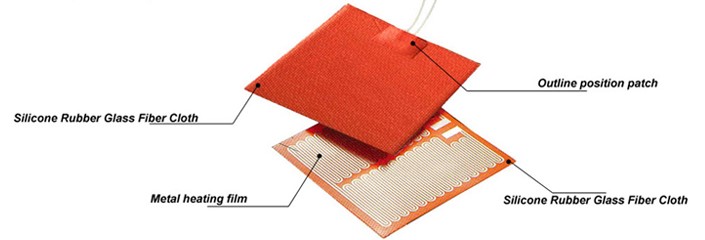

Designing custom silicone rubber heaters requires balancing factors like wattage, voltage, size, shape, thermal control, and mounting options. By addressing these considerations, you can create heaters tailored to your application's needs, ensuring optimal performance and reliability. Whether for medical devices, industrial equipment, or consumer electronics, customized silicone heaters provide versatile and effective heating solutions.

At HRX Heaters, we specialize in high-quality custom silicone heaters. Our expertise ensures you receive reliable and efficient heating solutions tailored to your unique demands. Trust HRX Heaters for unparalleled performance and service.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.