Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

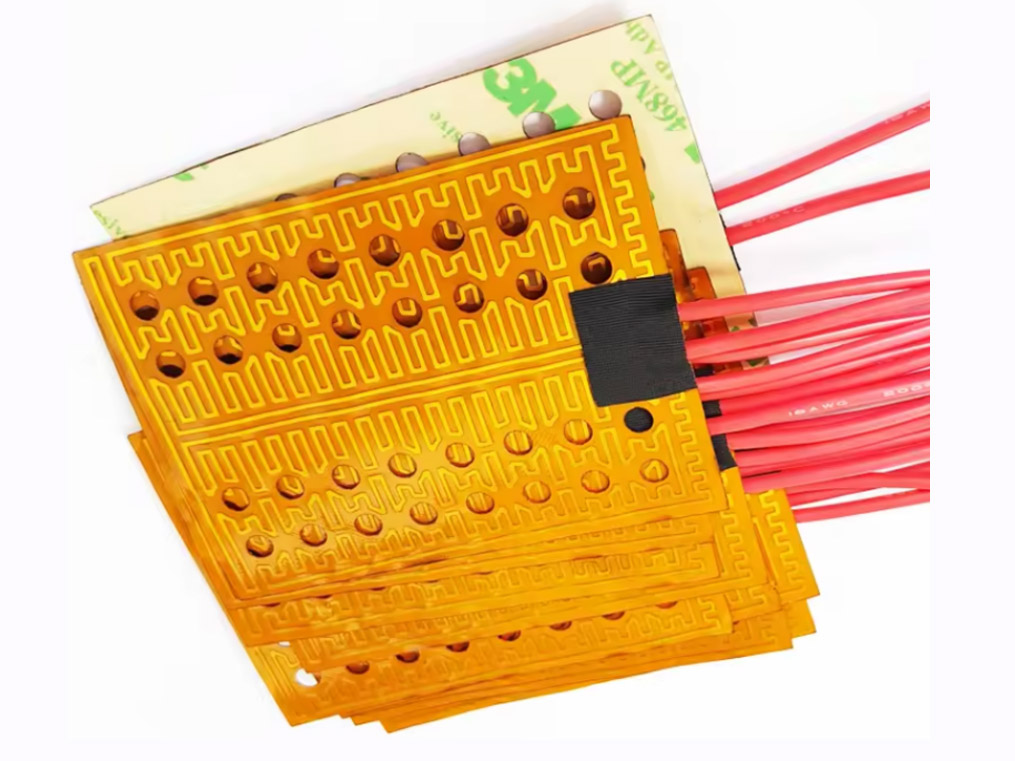

Polyimide Heaters are heating elements made from polyimide material, which boasts excellent properties such as high-temperature resistance, corrosion resistance, and electrical insulation. They are capable of operating reliably over a wide temperature range, withstanding temperatures up to 300°C and above.

The inclusion of air escape holes in the design of Polyimide Heaters is vital for ensuring their smooth operation. Here are scenarios where you might consider adding air escape holes:

High-Temperature Applications: When operating at high temperatures, the internal gases expand, increasing pressure. Without air escape holes, this could lead to deformation or damage of the heater.

Rapid Heating: In applications requiring quick temperature increases, air escape holes help to release internal pressure, preventing the heater from rupturing.

Sealed Structures: For heaters with sealed designs, air escape holes help balance internal and external pressure differences, preventing seal damage.

As we delve deeper into the mechanics of polyimide heaters, we'll uncover the myriad benefits that air escape holes bring to the table, from enhancing safety to improving performance and longevity. Let's explore how these humble holes make a significant difference in the effectiveness of polyimide heater design.

Extended Lifespan: By incorporating air escape holes, the internal pressure is effectively reduced, preventing damage from excessive pressure, thereby extending the heater's lifespan.

Improved Safety: Air escape holes help prevent explosive failures due to internal pressure buildup, thus reducing safety risks.

Enhanced Heating Efficiency: The release of internal pressure through air escape holes aids in better heat transfer between the heating element and the object being heated, improving heating efficiency.

Having highlighted the benefits of air escape holes, we now turn to the art of their design. In the next section, we'll discuss key considerations for optimizing air escape holes, from size and quantity to strategic placement, ensuring peak performance and durability in polyimide heater design. So when designing air escape holes, the following factors should be taken into account:

Hole Size: The size of the air escape holes should be selected based on the heater's operating environment and temperature to balance internal and external pressure differences.

Number of Holes: The number of air escape holes should be determined by the size of the heater and the requirements of its application—too many or too few can affect heating performance.

Placement: Air escape holes should be evenly distributed to ensure uniform internal pressure.

A well-designed air escape hole system not only ensures the proper functioning of the heater but also enhances its safety and longevity. If you have any design question about air escape holes, please feel free to contact us at sales@hrx-heaters.com.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.