Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

Maximize Your Silicone Heating Pad's Lifespan with These Simple Steps

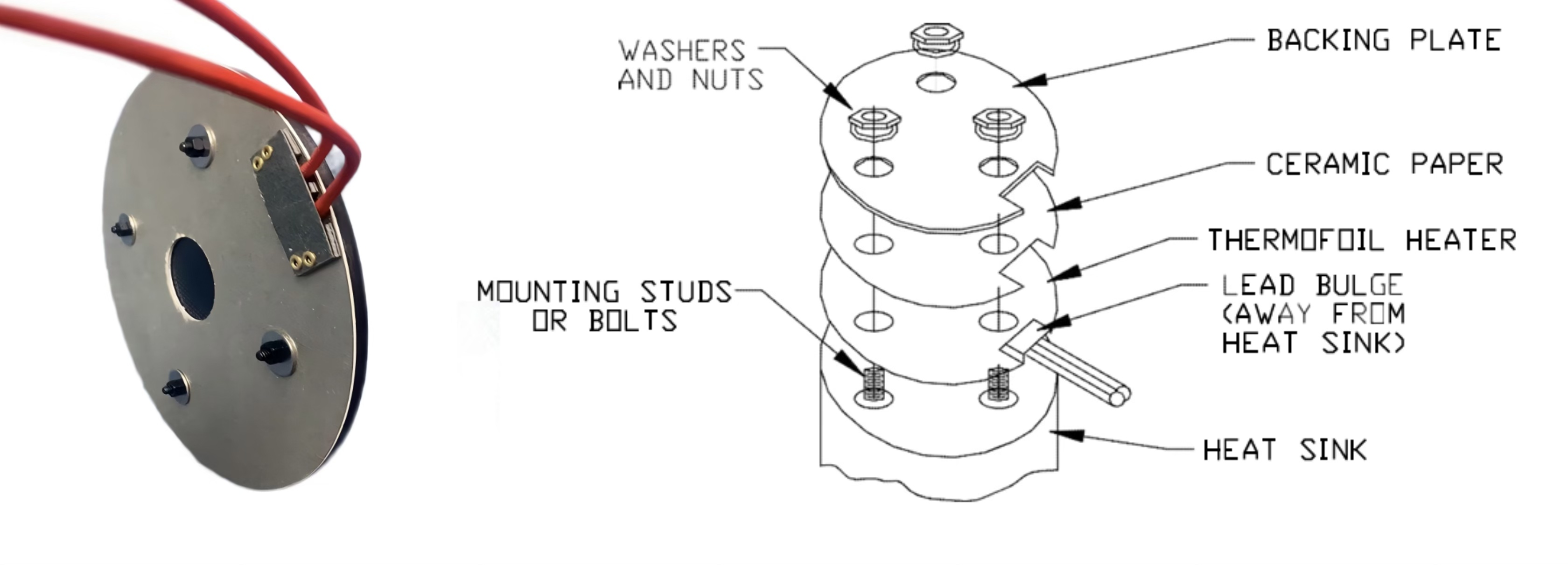

Mica heaters are widely used in various industrial and household heating applications due to their excellent thermal conductivity, electrical insulation, and durability. One of the key design features of these heating elements is the inclusion of multiple through-holes. These holes, which may include screw holes, ventilation holes, or other types of openings, are not just random design choices—they serve critical functions that enhance the performance, safety, and longevity of the heating element. In this blog, we’ll explore the reasons behind this design, focusing on three main points: even fixation, heat dissipation, and adaptability to different installation requirements.

Through-holes, particularly screw holes, play a vital role in achieving even fixation of the mica heating element. When a heating element is installed, it needs to be securely and uniformly attached to the heating device or surface. Uneven fixation can lead to several issues:

Hot Spots: If the heating element is not evenly fixed, certain areas may experience higher stress or pressure, leading to localized overheating, also known as hot spots. These hot spots can degrade the material over time and reduce the efficiency of the heating element.

Mechanical Stress: Uneven fixation can also cause mechanical stress, which may lead to warping or cracking of the mica sheet. This not only affects the performance but can also pose safety risks.

By distributing the through-holes evenly across the heating element, manufacturers ensure that the pressure is uniformly applied, minimizing the risk of hot spots and mechanical stress. This results in a more reliable and consistent heating performance.

Heat dissipation is another critical factor that influences the design of mica heating elements. While mica itself is an excellent insulator, the heat generated by the resistive wires embedded within the element needs to be effectively transferred to the target surface. Multiple through-holes play a significant role in this process:

Improved Airflow: The through-holes allow for better airflow around the heating element, which helps in dissipating excess heat. This is particularly important in high-temperature applications where overheating can lead to premature failure of the element.

Preventing Overheating: By facilitating heat dissipation, the through-holes help maintain a stable temperature across the heating element. This prevents localized overheating, which can damage the mica sheet or the resistive wires, thereby extending the lifespan of the heating element.

Thermal Expansion Management: Mica heating elements are subject to thermal expansion and contraction during heating and cooling cycles. The through-holes provide some flexibility, allowing the element to expand and contract without causing structural damage.

Another advantage of having multiple through-holes is the flexibility it offers in terms of installation. Different heating devices and applications have varying requirements when it comes to mounting heating elements. The presence of multiple through-holes allows for:

Versatile Mounting Options: Whether the heating element needs to be mounted vertically, horizontally, or at an angle, the multiple through-holes provide various options for secure attachment. This versatility makes mica heating elements suitable for a wide range of applications, from industrial ovens to household appliances.

Customizable Configurations: In some cases, the heating element may need to be customized to fit a specific device or surface. The multiple through-holes allow for easy modification or adaptation, ensuring a perfect fit without compromising on performance or safety.

Ease of Replacement: When it comes to maintenance or replacement, having multiple through-holes simplifies the process. Technicians can easily remove and replace the heating element without the need for specialized tools or complex procedures.

The inclusion of multiple through-holes in mica heating pads is not just a design quirk—it’s a carefully considered feature that enhances the performance, durability, and versatility of the heating element. By ensuring even fixation, improving heat dissipation, and offering adaptability to different installation requirements, these through-holes play a vital role in making mica heating elements a reliable choice for various heating applications.

Whether you’re designing a new heating system or maintaining an existing one, understanding the importance of these through-holes can help you make informed decisions and optimize the performance of your heating elements. So, the next time you see a mica heater with multiple through-holes, you’ll know that each one serves a purpose in delivering efficient and reliable heat.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.