The Industrial Ascent of Heating Membranes

Analyzing the Current Standing and Mapping Out the Future Landscape in Industrial Production

Heating membranes have progressively and conspicuously emerged as a cardinal element in industrial production, chiefly attributable to their salient and distinctive merits such as highly efficient heat conduction and remarkably pliable installation modalities.

In recent epochs, the utilization of heating membranes in industrial production has been on an unremitting and expansive spree. Notwithstanding, certain impediments like the intricate management of costs and the challenges associated with ensuring compatibility across diverse industrial milieus still tenaciously linger.

Heating membranes, adroitly affixed to the exterior of chemical reactor vessels, play an instrumental and decisive role in precisely modulating the reaction temperature. This is of superlative significance as it incontrovertibly vouches for the stability and efficacy of chemical reactions, especially those that are acutely and exquisitely sensitive to the minutest temperature fluctuations. For instance, in the elaborate and exacting production of high-purity pharmaceuticals, the maintenance of an unerringly precise temperature range is not only vital but also sine qua non to ensure the uncompromised quality and purity of the final product.

Within the extensive and elaborate network of industrial pipeline systems that ferry diverse fluids, heating membranes serve as an impregnable safeguard against the perils of freezing in frigid and inhospitable climes. They deftly sustain the fluid in a continuously flowing and unobstructed condition by furnishing a seamless and uninterrupted supply of heat, thereby effectively precluding the occurrence of blockages and adroitly averting potential damage to the pipelines. A quintessential and illustrative example is manifest in the oil and gas industry, where long-distance pipelines traverse extremely cold and challenging regions. The heating membranes, in such scenarios, ensure the seamless and uninterrupted transportation of crude oil and natural gas, thereby obviating costly and disruptive shutdowns that could otherwise ensue due to freezing.

In the food and pharmaceutical industries, heating membranes are strategically deployed in drying procedures. They possess the remarkable capacity to uniformly heat the products, thereby expediting the evaporation of moisture in a controlled and efficient manner and safeguarding the quintessential quality and safety of the end products. In the production of dehydrated food products such as dried fruits and vegetables, the heating membrane's unique ability to dispense gentle and evenly distributed heat is not only essential but also pivotal in preserving the nutritional value and flavor of the food, thereby ensuring that the end consumers can relish products of the highest caliber.

With the ceaseless and relentless advancement of technology, heating membranes are poised on the cusp of witnessing even more substantial and remarkable growth within the industrial production industry. The prospective augmentation of heating efficiency, coupled with the continuous evolution of intelligent control systems, will incontrovertibly render heating membranes more accurate, energy-efficient, and technologically sophisticated. Moreover, the anticipated broadening of application arenas and the synergistic amalgamation with novel and cutting-edge materials will also usher in a plethora of novel opportunities and concomitant challenges that will shape the future trajectory of this dynamic field.

The heating membrane undeniably harbors extensive and far-reaching application vistas in the industrial production industry. Through unceasing innovation and perpetual enhancement, it is slated to assume an even more central and pivotal role in impelling the industrial production paradigm to evolve towards greater specialization, precis

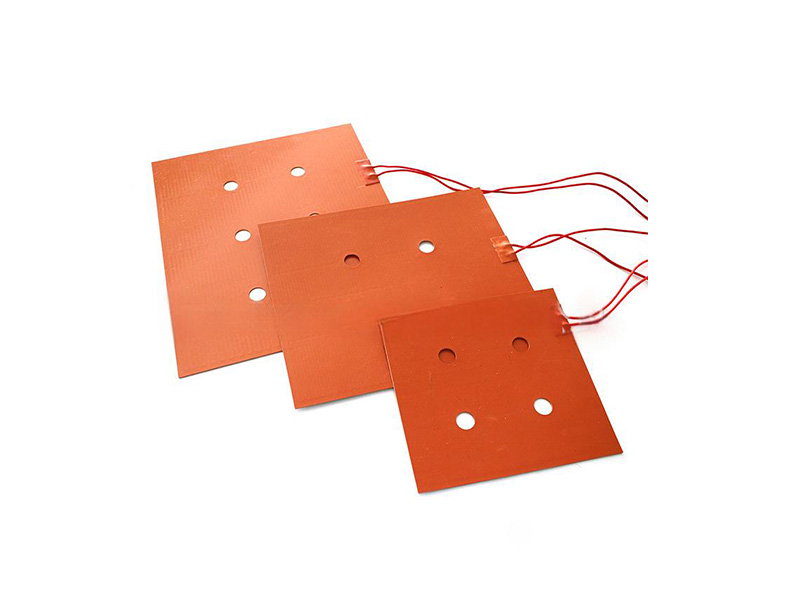

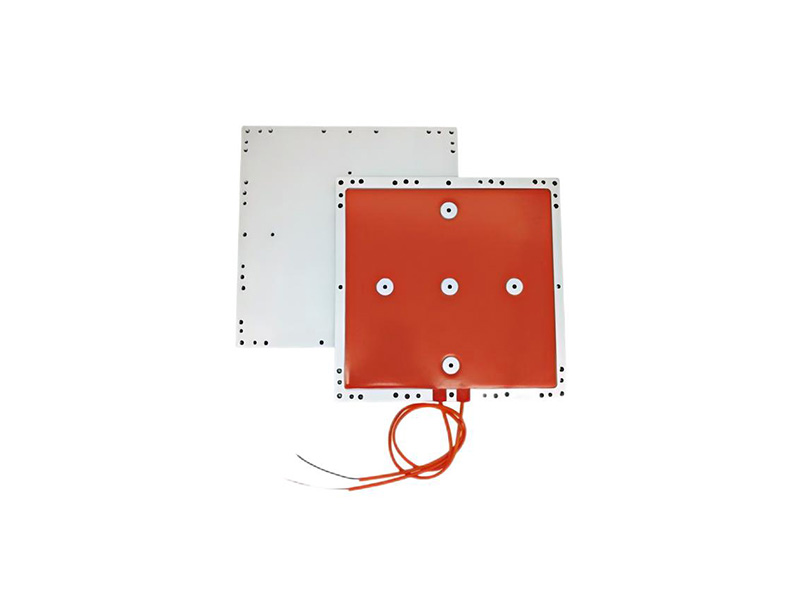

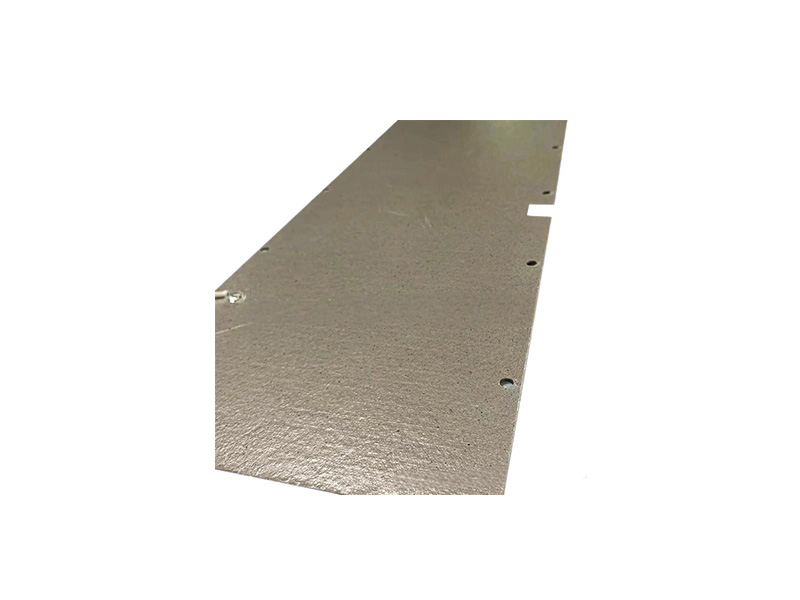

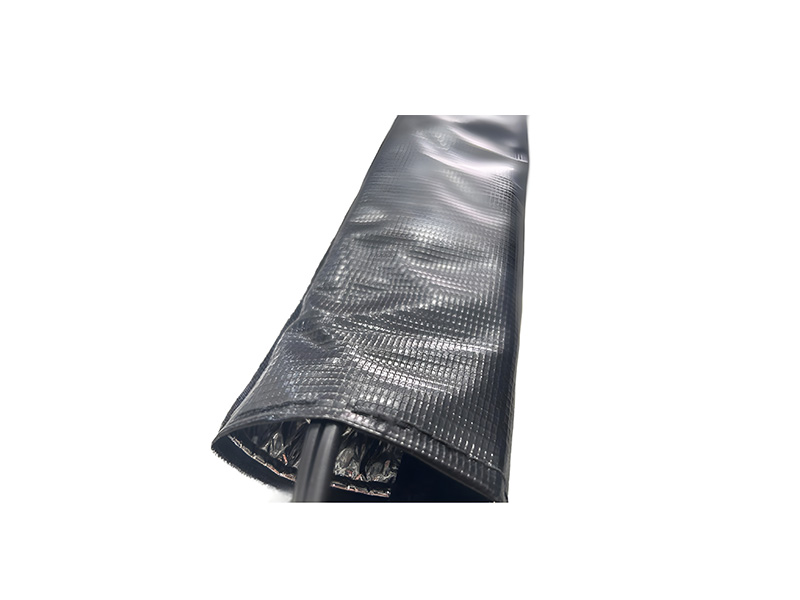

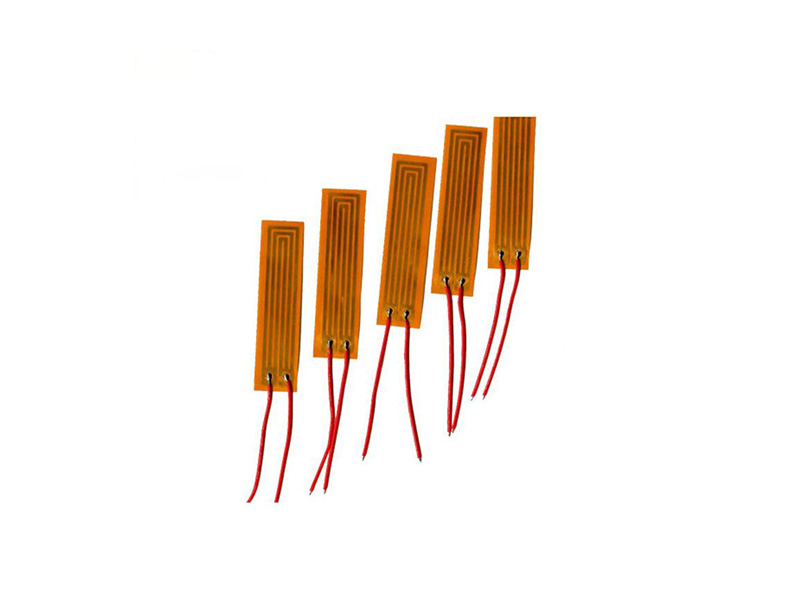

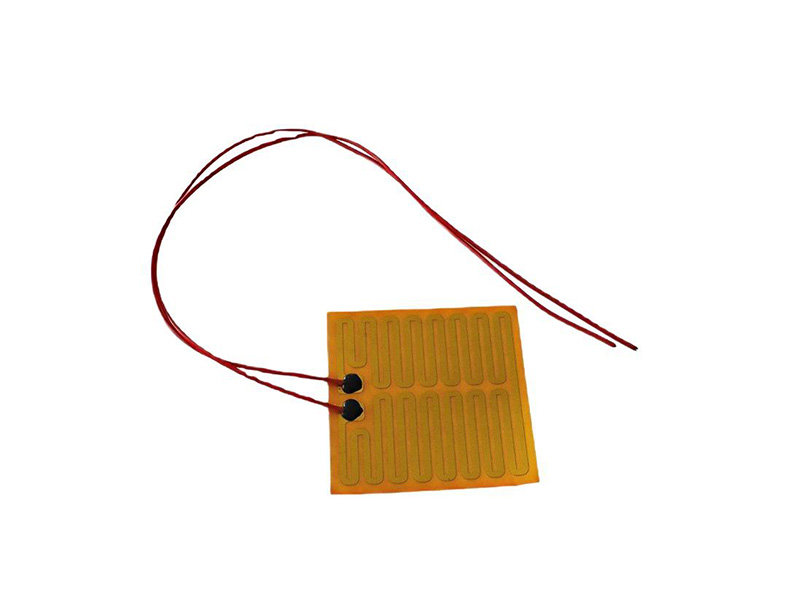

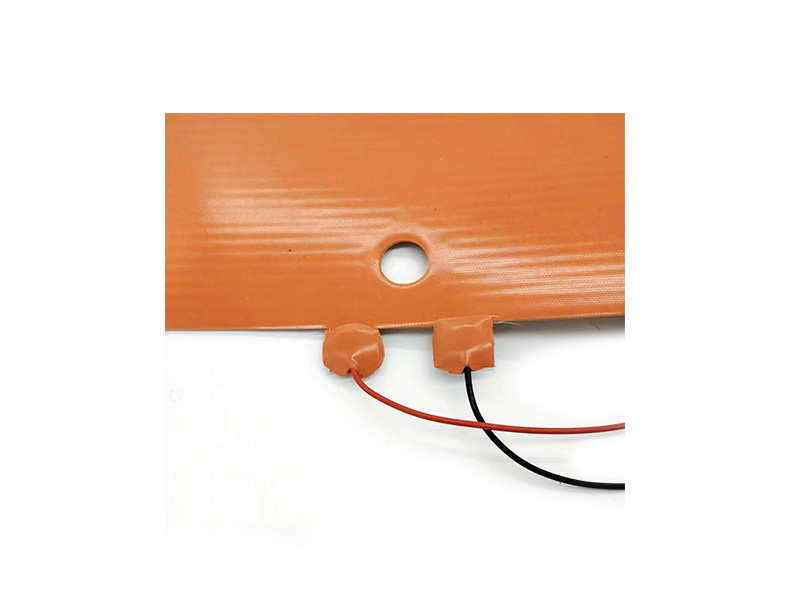

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.