Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

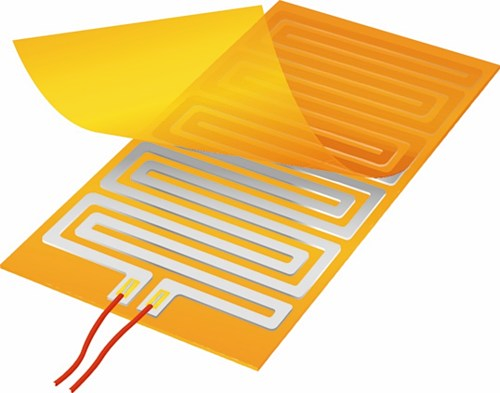

Flex heaters, known for their versatility and efficiency, are widely used in various industries including aerospace, medical devices, and electronics. To ensure their longevity and optimal performance, it is crucial to follow certain precautions during and after installation. In this blog post, we will detail important after-sales precautions for Flex heaters to help you avoid common pitfalls and maximize the lifespan of your heating elements.

One of the most critical precautions is to ensure that the Flex heater is not operated beyond its rated voltage. Operating the heater at a higher voltage can increase the temperature beyond the safe limit, leading to potential damage or burnout.

Key Points:

Always check the rated voltage specified by the manufacturer before powering the heater.

Use a reliable power source and consider using voltage regulators to maintain a consistent voltage supply.

Regularly monitor the heater's performance to ensure it is operating within the safe voltage range.

Flex heaters are designed to be flexible but should not be subjected to excessive mechanical stress such as tearing, folding, or twisting. Such actions can damage the heater's internal structure and render it ineffective.

Key Points:

When installing or repositioning the heater, handle it gently to avoid physical damage.

Avoid sharp bends or folds that can create stress points and potentially break the heater.

Store Flex heaters in a flat or rolled position as recommended by the manufacturer to prevent unintended damage.

For Flex heaters used in high voltage applications, maintaining the integrity of the surface is paramount. Any punctures or damage to the protective film can result in electrical leakage or short circuits.

Key Points:

Inspect the heater surface regularly for any signs of damage or wear.

Ensure that the protective film remains intact and avoid using sharp objects near the heater.

If damage is detected, consult the manufacturer for repair options or consider replacing the heater to maintain safety.

Proper adhesion of the Flex heater to the substrate is essential for effective heat transfer. Poor adhesion can lead to uneven heating and potential overheating of the heater itself, commonly referred to as "dry burning."

Key Points:

Clean the substrate surface thoroughly before applying the heater to ensure strong adhesion.

Press the heater evenly onto the surface to eliminate air bubbles and ensure full contact.

Follow the manufacturer's instructions for adhesive application and curing times to achieve optimal results.

By following these after-sales precautions, you can ensure the longevity and efficient performance of your Flex heaters. Avoiding excessive voltage, handling the heaters with care, maintaining surface integrity, and ensuring proper adhesion are key steps to prevent damage and optimize heat transfer. At HRX Heaters, we provide detailed guidelines and support to help you get the most out of your Flex heaters. Trust in our expertise and commitment to quality for all your heating needs. HRX Heaters – Your partner for reliable heating solutions.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.