Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

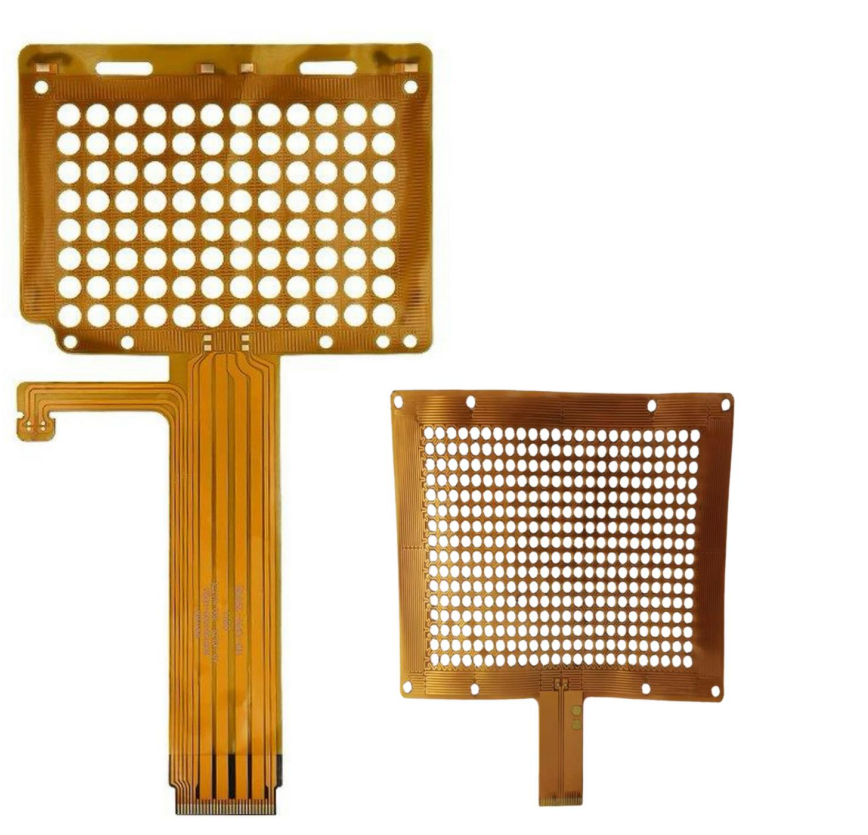

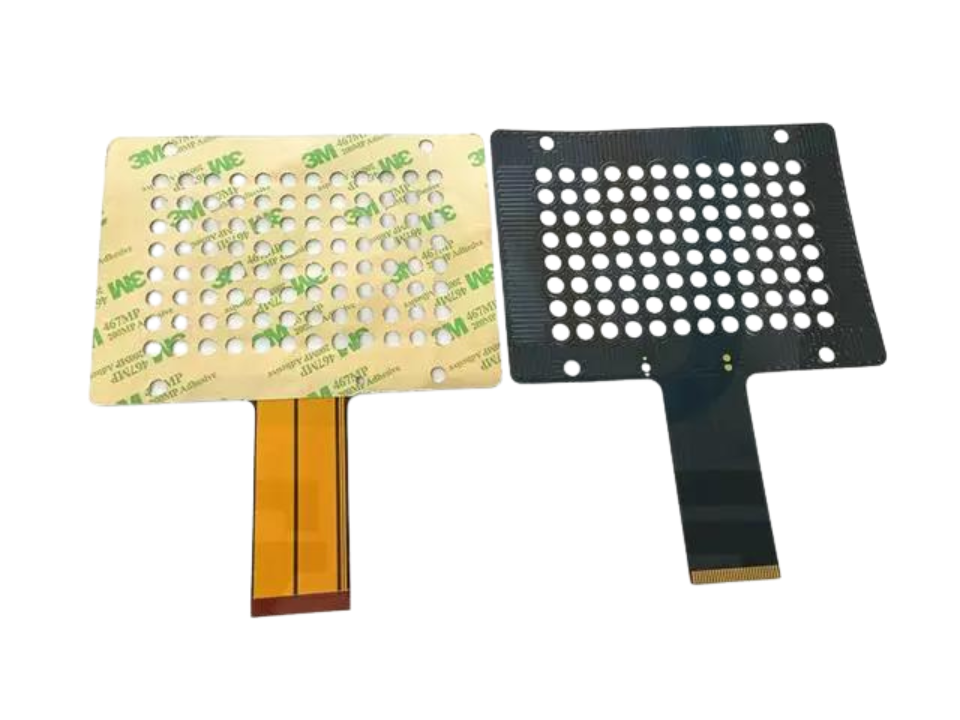

When most people think of Polyimide heaters, they often envision straightforward designs: rectangular or circular shapes with neatly etched metal lines, typically with two leads extending out for soldering wire connections. However, the reality is that Polyimide heaters offer a far broader range of possibilities, much like Flexible Printed Circuits (FPCs).

Polyimide heaters are not limited to simple forms. They share a key feature with FPCs: the use of copper foil conductors. What sets them apart is the Polyimide material, which serves as an excellent insulator. This insulation capability enables more sophisticated designs that integrate many features commonly associated with FPCs.

Polyimide heaters can be customized in ways that extend far beyond basic geometric shapes. For instance:

Via Integration: Just like in FPCs, Polyimide heaters can be designed with vias—holes that allow connections between different layers of the heater. This feature is especially useful for creating compact and efficient thermal solutions in multi-layered applications.

Custom Solder Pads: You can design Polyimide heaters with solder pads, facilitating the attachment of various components directly to the heater. This makes it easier to integrate the heater into complex electronic systems.

Cable-Like Design: The circuitry of a Polyimide heater can be crafted to function as a cable. This flexibility allows the heater to be used in applications where flexible connections are needed.

Gold Fingers: For easy integration with connectors, Polyimide heater designs can include gold fingers. These are specialized conductive pads that can be directly inserted into connectors, ensuring reliable and straightforward connectivity.

Polyimide Color Flexibility

Polyimide heaters are available in a range of colors such as yellow, black, and white. This color variety not only enhances the visual appeal of your products but also allows for better alignment with design aesthetics and branding requirements.

Multi-Layer Capabilities

For more advanced applications, we offer Polyimide heaters with 2 to 4 layers of conductors. Multi-layer Polyimide heaters provide enhanced thermal management and can support more complex heating profiles. This capability is ideal for applications that require precise temperature control and efficient heat distribution.

Applications and Advantages

The versatility of Polyimide heaters makes them suitable for a wide range of applications, including:

· Consumer Electronics: Heating elements in devices like smartphones, tablets, and wearables.

· Medical Devices: Precise heating solutions for diagnostic and therapeutic equipment.

· Automotive: Heating for components and systems within vehicles.

· Industrial Equipment: Customized heating solutions for machinery and production lines.

In summary, Polyimide heaters offer a remarkable degree of customization and flexibility. Far from being limited to simple shapes and designs, they can be tailored to meet specific requirements, whether through advanced layer configurations, integrated features, or aesthetic options. Their ability to combine functionality with versatility makes Polyimide heaters an excellent choice for innovative thermal management solutions across various industries.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.