How Aluminium Foil Heaters Work and Where to Use Them?

How PI Graphene Heating Films Achieve "Instant Heat-up" and "Ultra-Low Energy Consumption"?

12 Safety & Longevity Guidelines Before Installation for Flexible Film Heaters

Battery Drying & Formation Equipment Heating Plate

How Flexible Heaters Achieve Consistent Medical Fluid Warming?

Polyimide heaters are widely used in various applications that require precise temperature control and uniform heating. These heaters are known for their flexibility, durability, and high thermal stability, making them ideal for use in demanding environments. However, to enhance their performance and efficiency, it is common to add a layer of thermal insulation cotton on the surface of the polyimide heater. In this blog, we will explore the purpose of this addition and discuss the types of products that typically use polyimide heaters with thermal insulation cotton.

The primary function of thermal insulation cotton is to reduce heat loss and improve the efficiency of the heating process. When a polyimide heater operates, it generates heat that needs to be directed toward the desired target, whether it's a component, surface, or environment. Without proper insulation, a significant portion of this heat can be lost to the surrounding environment, leading to inefficiencies and potentially higher energy consumption.

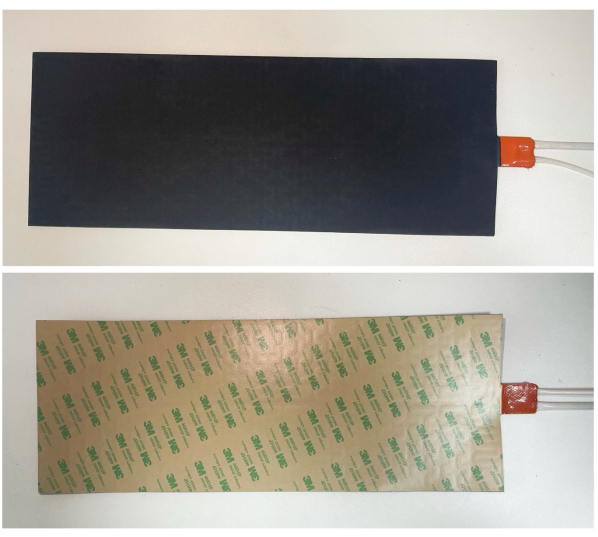

Thermal insulation cotton (the black color in below picture) acts as a barrier that traps heat within the desired area, ensuring that the majority of the generated heat is used effectively. This not only enhances the performance of the polyimide heater but also helps maintain a more consistent temperature. Additionally, the insulation layer can protect surrounding components from exposure to excessive heat, reducing the risk of damage.

Polyimide heaters with thermal insulation cotton are commonly used in products and applications where precise temperature control and energy efficiency are critical. Some of these applications include:

Battery Warming Systems: In electric vehicles or other battery-operated devices, maintaining an optimal battery temperature is crucial for performance and longevity. Polyimide heaters with thermal insulation cotton help ensure that the battery operates within the desired temperature range, even in cold environments.

Medical Devices: Many medical devices, such as incubators, diagnostic equipment, and patient warming systems, require precise and uniform heating. The addition of thermal insulation cotton ensures that the heat is efficiently directed to the patient or device, improving safety and effectiveness.

Aerospace Applications: In aerospace, components often need to be heated or kept at a specific temperature in extremely cold environments. Polyimide heaters with thermal insulation cotton are used to maintain these temperatures while minimizing energy consumption, which is critical in such applications.

Industrial Equipment: Machinery and equipment used in industrial settings, such as 3D printers, sensors, and analytical instruments, often incorporate polyimide heaters. The insulation ensures that heat is concentrated where it is needed most, improving process efficiency and reducing waste.

The addition of thermal insulation cotton to polyimide heaters plays a crucial role in enhancing the efficiency and performance of these heating elements. By reducing heat loss and ensuring that the generated heat is effectively used, this insulation improves energy efficiency and helps maintain precise temperature control. Polyimide heaters with thermal insulation cotton are essential in applications where accurate temperature management is critical, such as in battery systems, medical devices, aerospace, and industrial equipment.

With the right combination of polyimide heaters and thermal insulation cotton, you can achieve optimal heating performance, energy savings, and increased longevity of your products. Below, you can see a photo of a polyimide heater with thermal insulation cotton, showcasing how this combination is applied in real-world scenarios.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.