Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

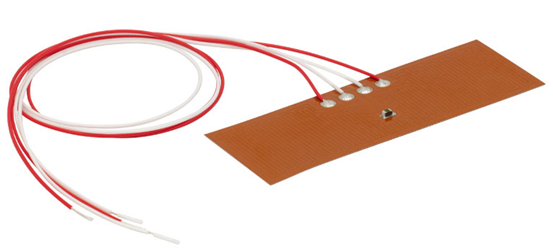

Polyimide heaters, also known as Kapton heaters, are highly efficient and versatile heating solutions widely used in various industries. Known for their flexibility, durability, and excellent thermal properties, these heaters are designed to provide consistent and reliable heat output. But how exactly do polyimide heaters achieve the desired temperatures? In this blog, we will explore the key factors that contribute to the efficient temperature control of polyimide heaters.

Polyimide heaters are made from polyimide film, a material known for its exceptional thermal stability and insulating properties. This film can withstand a wide range of temperatures, from as low as -200°C to as high as 260°C, without degrading. The resistance to extreme temperatures ensures that the heater can operate efficiently and reliably under various conditions.

The construction of polyimide heaters involves embedding a thin, flexible heating element, typically made from metal conductor, between layers of polyimide film. The heating element is designed with precision to ensure even heat distribution across the surface of the heater. The etched foil can be customized in terms of pattern and thickness to achieve specific heating requirements, enabling precise temperature control.

3. Power Density

Power density, measured in watts per square inch (W/in²), is a critical factor in determining the heating performance of polyimide heaters. By adjusting the power density, manufacturers can control the heat output of the heater. Higher power densities result in higher temperatures, while lower power densities provide more moderate heating. This flexibility allows polyimide heaters to be tailored to meet the specific thermal requirements of different applications.

To achieve and maintain the desired temperature, polyimide heaters are often used in conjunction with advanced temperature control systems. These systems typically include sensors, such as thermocouples or RTDs (Resistance Temperature Detectors), which monitor the heater's temperature in real-time. The data from the sensors is fed into a temperature controller, which adjusts the power supplied to the heater to maintain the target temperature. This closed-loop system ensures precise temperature regulation and prevents overheating or underheating.

Effective thermal insulation is essential for achieving the desired temperature efficiently. Polyimide heaters can be paired with insulating materials to minimize heat loss and ensure that the heat generated is directed towards the target area. This not only improves the efficiency of the heating process but also helps in maintaining stable temperatures over extended periods.

The operating environment plays a significant role in achieving the desired temperature with polyimide heaters. Factors such as ambient temperature, airflow, and the thermal properties of the materials being heated can affect the heater's performance. Understanding these environmental factors and designing the heating system accordingly can help in achieving optimal temperature control.

Polyimide heaters are versatile and efficient heating solutions capable of achieving precise temperature control through a combination of advanced materials, thoughtful design, appropriate power density, sophisticated temperature control systems, and effective thermal insulation. By considering these factors, manufacturers and users can ensure that polyimide heaters deliver consistent and reliable heating performance for a wide range of applications.

At HRX Heaters, we specialize in providing high-quality polyimide heaters tailored to meet the specific needs of our clients. Our expertise in design and manufacturing ensures that you receive a product that delivers optimal performance and reliability. Contact us today to learn more about how our polyimide heaters can meet your heating requirements.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.