Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

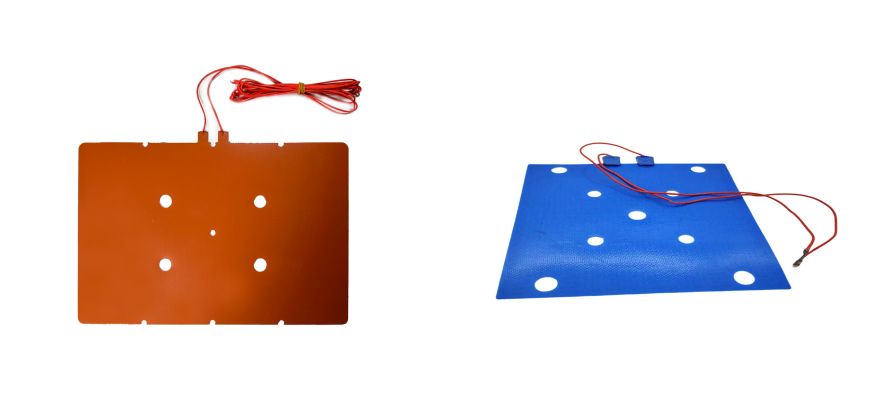

In our everyday lives, the silicone heaters we encounter are often a recognizable orange color. This is because orange is the standard color for silicone rubber material. However, many customers, especially those who design complex machines, seek more tailored solutions to match their aesthetic or functional needs. The good news is that silicone heaters can indeed be customized in a variety of colors, making them versatile components for a range of design applications.

The default orange hue is not arbitrary; it’s the result of the natural color of silicone rubber combined with its heat-resistant properties. This bright color also makes silicone heaters easy to spot in industrial settings, providing a safety advantage by clearly marking heated areas.

While orange is practical, it's not always ideal for all applications. Some customers prefer their heaters to blend seamlessly with the rest of their equipment or branding. In such cases, silicone heaters can be customized in a range of colors. Common custom colors include blue, gray, green, and black, among others. These alternative colors allow manufacturers to achieve a cohesive design without compromising functionality.

When opting for a custom color, there are a few important things to consider:

1. MOQ (Minimum Order Quantity): Custom colors generally require a minimum order quantity, as the material must be specially prepared in the desired shade. This makes custom colors more suited to larger production runs.

2. Cost: Custom-colored silicone materials are typically priced higher than the standard orange version. This is due to the additional processes and resources required to produce specific colors. However, for customers with specific design or branding needs, this added investment is often worthwhile.

3. Lead Times: Customization can also affect the production time. Depending on the availability of pigments and other factors, lead times may be longer for custom-colored heaters compared to their standard orange counterparts.

Choosing a custom color for your silicone heater isn’t just about aesthetics. Here are a few key benefits:

1. Branding: For companies that prioritize a consistent brand identity, having machinery components in their brand colors can enhance the overall look of their products.

2. Integration with Equipment: Custom-colored heaters can better match the machines they are installed in, creating a more integrated and sleek appearance.

3. Visual Coding: Different colors can be used for easy identification of different heater types or temperature ranges, especially in complex installations.

Silicone heaters are a versatile and essential component in many industries. While the standard orange serves its purpose well, the availability of custom colors adds flexibility to design and branding possibilities. If you’re looking to match your heaters to your machinery or simply want something that stands out, customizing the color of your silicone heaters might be the perfect solution. Keep in mind the requirements for MOQ and potential cost implications, but rest assured that with these customizations, your design can reach the next level.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.