Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

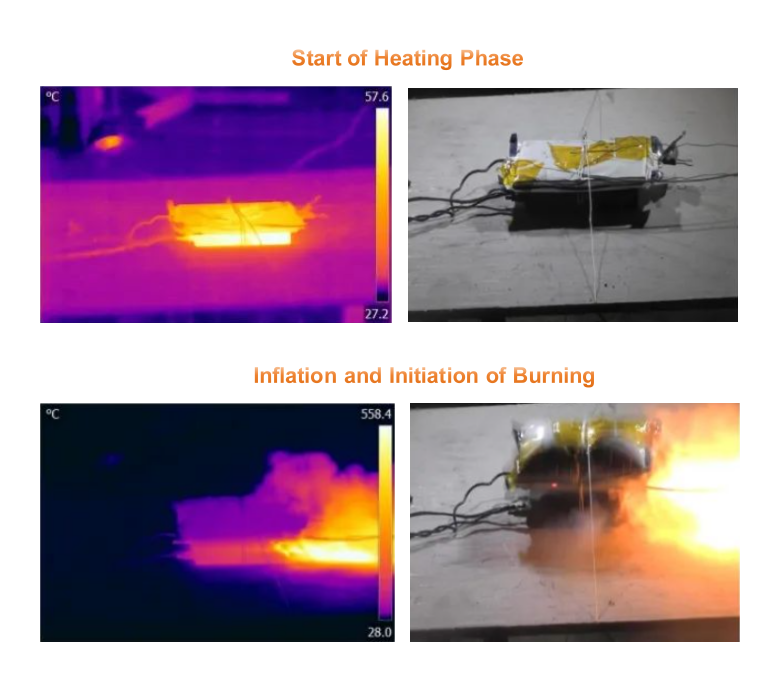

Battery safety is a top priority in today’s world of energy storage and electrification. One key aspect of this safety is addressing the phenomenon known as "thermal runaway." Thermal runaway occurs when the temperature of a battery rises uncontrollably, potentially leading to fire or explosions. To ensure battery safety under high-stress conditions, the thermal runaway test is conducted. This test simulates how a battery reacts to extreme heat, and it plays a critical role in evaluating the thermal stability of the battery.

Thermal runaway testing is crucial for multiple reasons:

Ensuring Safety Under Extreme Conditions: The test helps manufacturers understand how a battery behaves under high-temperature scenarios, such as overheating or exposure to extreme environmental conditions.

Preventing Catastrophic Failures: Batteries, especially in high-power applications, can be prone to thermal runaway, which can cause fires or explosions. Conducting this test ensures the battery can safely dissipate heat without catastrophic failure.

Meeting Regulatory and Industry Standards: Battery safety regulations require manufacturers to perform thermal runaway tests to certify that their products can be safely used in various applications, from electric vehicles to consumer electronics.

What Can This Test Prevent?

By identifying weaknesses in the thermal design of batteries, thermal runaway testing can:

Prevent Overheating and Fire: A battery that fails this test could potentially ignite or explode when exposed to high temperatures. Identifying this early on helps manufacturers develop safer designs.

Protect Equipment and Users: Ensuring the thermal stability of batteries means that equipment, vehicles, and users are protected from accidents caused by thermal runaway.

Increase Lifespan and Reliability: A battery that passes the thermal runaway test is more likely to have a longer life and consistent performance in various operating conditions.

The Role of Heaters in the Test

To accurately simulate thermal runaway, batteries need to be externally heated in a controlled environment. This is where heaters, such as Polyimide and Silicone heaters, play an essential role.

Polyimide Heaters: These are lightweight, flexible heaters that can provide precise and uniform heating. Their thin profile makes them ideal for applications where space is limited.

Silicone Heaters: These are more robust and can handle higher temperatures. They are suitable for larger batteries or more rugged testing environments.

Both of these heater types offer reliable performance, making them excellent choices for thermal runaway tests. By using our heaters, manufacturers can conduct thorough tests, ensuring that their batteries will remain safe in the field. Our heater solutions can be tailored to the specific needs of the battery being tested, providing customizable options for different testing scenarios.

Conclusion

Thermal runaway testing is a vital part of ensuring battery safety in modern applications. It helps prevent catastrophic failures, protects users, and ensures compliance with safety standards. Heaters, including Polyimide and Silicone models, play a key role in making this test effective by providing precise and controlled heating. By incorporating high-quality heaters into the testing process, manufacturers can be confident in the safety and reliability of their battery designs.

Encouraging industries to prioritize thermal runaway testing with proper heater solutions is an important step toward a safer and more sustainable future.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.