Does Your 3D Printer Need a Custom-Color Silicone Heater?

Do the Silicone Materials in Our Silicone Heaters Contain Fibers?

Understanding ITO Heater Thickness Impact on Resistance and Transparency

Transparent Heaters: Types, Sizes, Parameters, and Applications

Polyimide Heater with PT100 Sensor for Precision Thermal Management

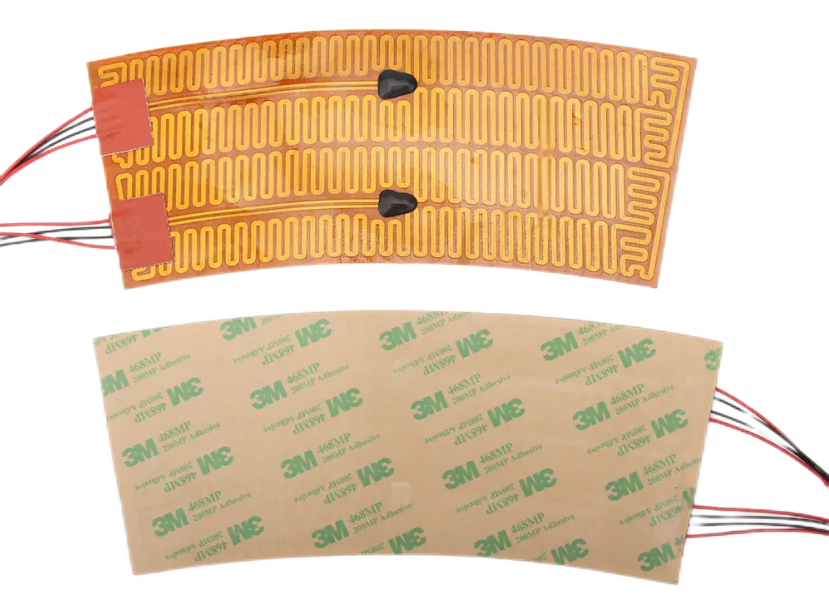

In the automotive industry, rearview mirrors with built-in defogging and defrosting capabilities are essential for safety and convenience. These systems rely on heating elements, and the material used in these elements significantly impacts performance, cost, and durability. Two common materials for defogging heating films are PET (Polyethylene Terephthalate) and PI (Polyimide). Below, we’ll explore their differences and help you determine the best choice for your application.

Advantages:

Cost-effective: PET is a more economical option, making it ideal for large-scale production and cost-sensitive applications.

Good processability: PET is easy to form and shape, allowing manufacturers to create films of various sizes and designs efficiently.

High transparency: The material’s optical clarity makes it suitable for applications where maintaining visibility is crucial.

Limited heat resistance: PET struggles in high-temperature environments, which can impact its long-term stability.

Lower mechanical strength: Compared to PI, PET is less durable and may wear out more quickly in demanding conditions.

Advantages:

Exceptional heat resistance: PI can operate in higher temperature ranges without degrading, making it ideal for extreme conditions.

Superior mechanical strength: The material is highly durable and resistant to wear and tear, suitable for long-term use in harsh environments.

Chemical stability: PI withstands exposure to a wide range of chemicals, including solvents, acids, and alkalis, enhancing its reliability.

Disadvantages:

Higher cost: The material and processing costs of PI are significantly higher than PET, increasing overall production expenses.

Complex processing: PI’s properties make it more challenging to process, often requiring specialized techniques.

High temperatures: If your application involves prolonged exposure to high temperatures or extreme weather conditions, PI is the better choice due to its superior thermal stability.

Mild environments: For less demanding applications where temperatures are moderate, PET can deliver reliable performance at a lower cost.

Budget-friendly projects: PET’s affordability makes it ideal for projects with tight budgets and large production volumes.

Premium performance: If your project prioritizes durability and high performance over cost, PI is worth the investment.

High-performance applications: PI excels in scenarios requiring long-term stability, resistance to wear, and exposure to chemicals.

Standard performance needs: PET is sufficient for applications with lower performance demands.

Quick manufacturing: PET’s ease of processing makes it suitable for projects requiring rapid prototyping and large-scale production.

Precision designs: For intricate designs and high-precision requirements, PI’s properties can provide an advantage despite the added complexity.

Property | PET | PI |

Cost | Lower | Higher |

Heat Resistance | Moderate | Excellent |

Durability | Moderate | High |

Transparency | High | Low |

Ease of Processing | High | Moderate |

Chemical Stability | Moderate | High |

You need an economical solution for mild to moderate environments.

Transparency and ease of processing are critical.

Your application requires exceptional heat resistance and durability.

The operating environment involves extreme conditions or exposure to chemicals.

Choosing the right material for your defogging heating films can be challenging, especially when balancing performance, cost, and application requirements. If you’re unsure which material is best for your project, feel free to reach out to our experts at sales@hrx-heaters.com. We’ll help you find the perfect solution tailored to your needs.

Related product links

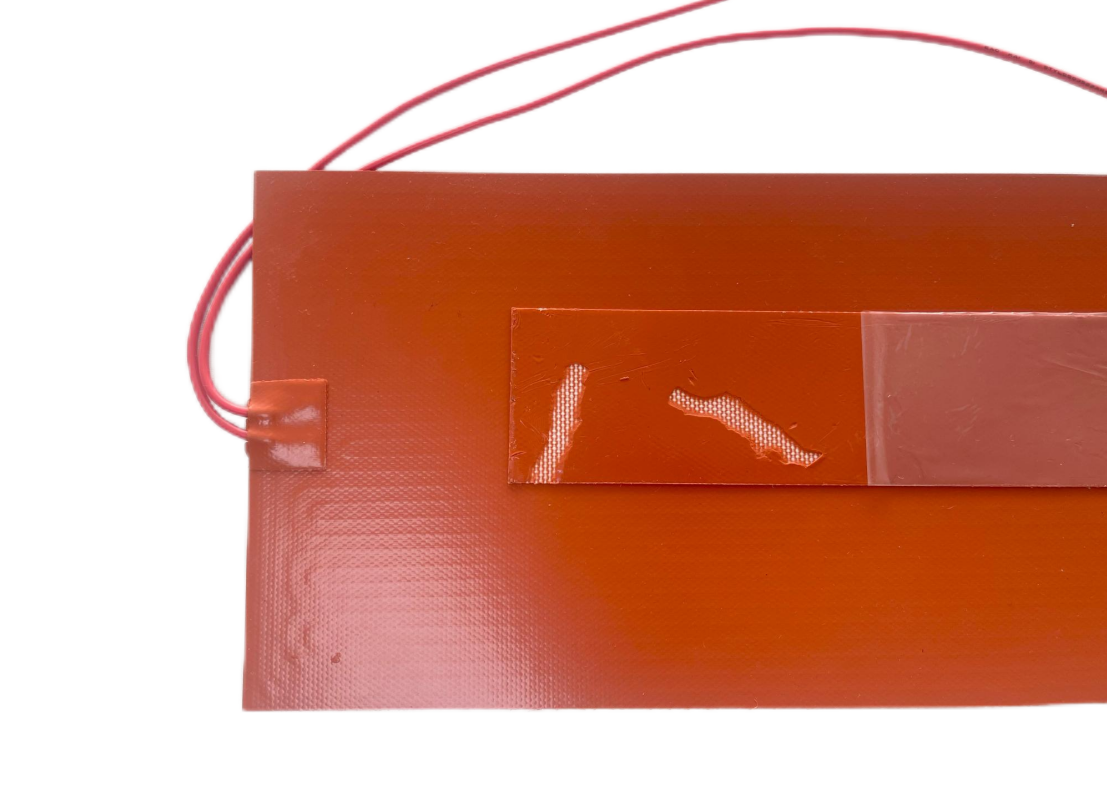

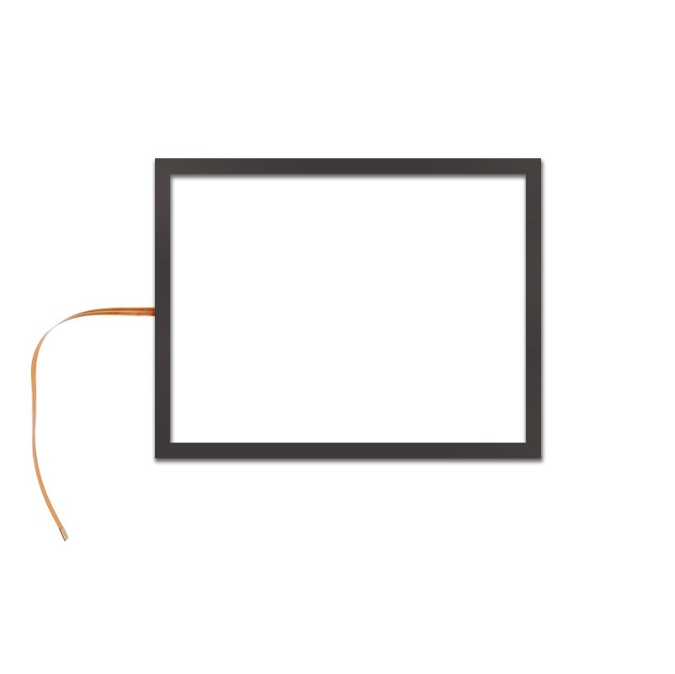

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.