Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

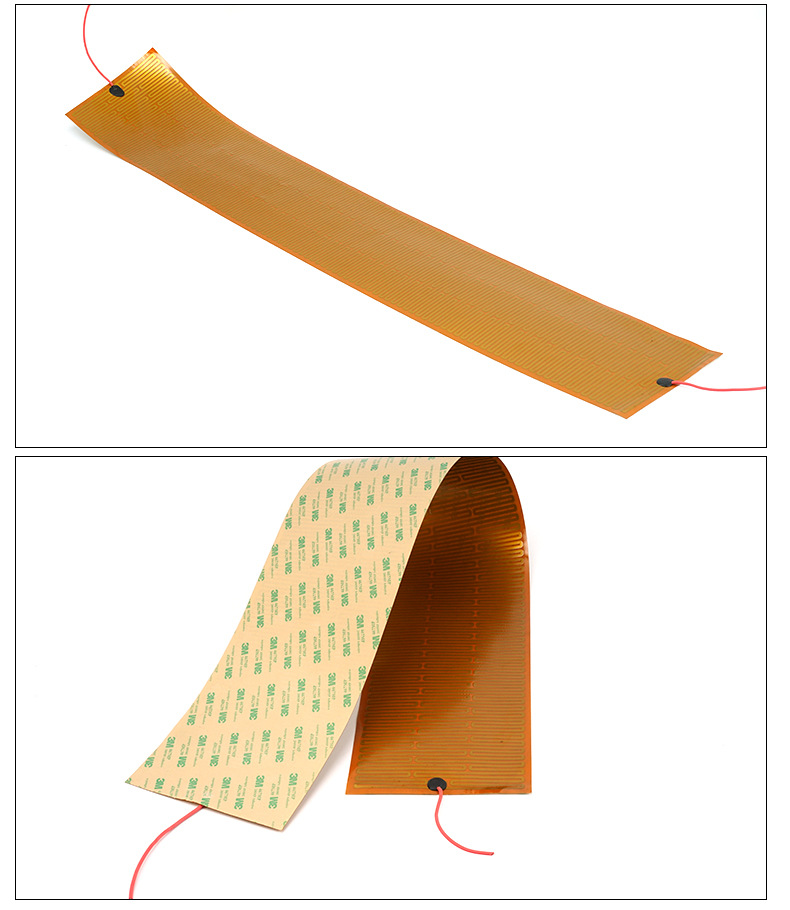

Polyimide heaters, known for their flexibility, lightweight construction, and durability, are a popular choice for industries requiring precise and efficient heating solutions. Their ability to perform under extreme temperature conditions makes them indispensable in aerospace, medical devices, electronics, and more. However, proper installation is critical to ensure these heaters function optimally and safely. Below is a simplified guide to help you correctly install Polyimide heaters.

To ensure a strong adhesive bond, the target surface must be clean and free from contaminants like oil, grease, or dust.

· Wipe the surface with a lint-free cloth.

· Use a solvent such as isopropyl alcohol or acetone for thorough cleaning.

· Allow the surface to dry completely before proceeding.

Careful positioning is essential for effective heating and adhesive performance.

· Place the heater onto the cleaned surface, aligning it correctly.

· Avoid touching the adhesive area to prevent contamination.

· Ensure the heater does not overlap with any other heaters or components.

Activating the adhesive and achieving full contact with the surface is crucial for optimal heat transfer.

· Peel back a small corner of the release cover.

· Press the heater onto the surface, starting from the exposed corner. Gradually peel away the remaining release cover while applying even pressure across the heater.

· Smooth out the heater to eliminate any air gaps, as they can cause uneven heating or damage.

To ensure proper adhesion, apply consistent pressure across the heater’s surface.

· Use a flexible material like a silicone pad to distribute pressure evenly.

· A pressure range of 150–250 psi is recommended for optimal bonding.

Properly securing the lead wires ensures the heater's integrity and prevents mechanical damage.

· Fix the lead wires in place to minimize stress on the heater.

· Avoid pulling or bending the wires excessively during installation.

· Avoid Repairs: Damaged Polyimide heaters should not be repaired. Always replace them to ensure safety and performance.

· Professional Installation: For best results, installation should be performed by qualified personnel familiar with electrical and thermal systems.

Polyimide heaters are versatile and reliable tools for various heating applications. By following these streamlined installation steps—cleaning the surface, positioning carefully, adhering with even pressure, and securing the wiring—you can achieve optimal heater performance and longevity. Always prioritize safety by avoiding repairs on damaged heaters and seeking professional assistance for installation when necessary.

With proper care and attention during installation, Polyimide heaters can provide efficient and consistent heating for years to come.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.