Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

Silicone rubber heaters are valued for their adaptability and performance across a variety of industries, including medical devices, automotive, food service equipment, aviation, and industrial applications. Their flexibility, durability, and ability to handle extreme temperatures make them a top choice for engineers and designers. To make the most of these heaters, consider these seven important factors:

1. Wide Temperature Range

Silicone rubber heaters perform reliably in extreme temperatures. They can operate continuously at temperatures up to 200°C and withstand short bursts of heat up to 300°C. Additionally, they stay flexible in cold conditions as low as -50°C, making them suitable for harsh environments.

2. High Dielectric Strength

With a dielectric strength ranging from 10 to 20kV/mm, these heaters ensure safe operation in various settings. Their high flammability resistance further adds to their reliability, making them a trusted solution for safety-critical applications.

3. Resistance to Environmental Stress

Built to endure tough conditions, silicone rubber heaters resist moisture, ozone, and some chemicals. They can also withstand vibration, thermal shocks, and mechanical strain, ensuring consistent performance even in demanding industrial environments.

4. Customization Options

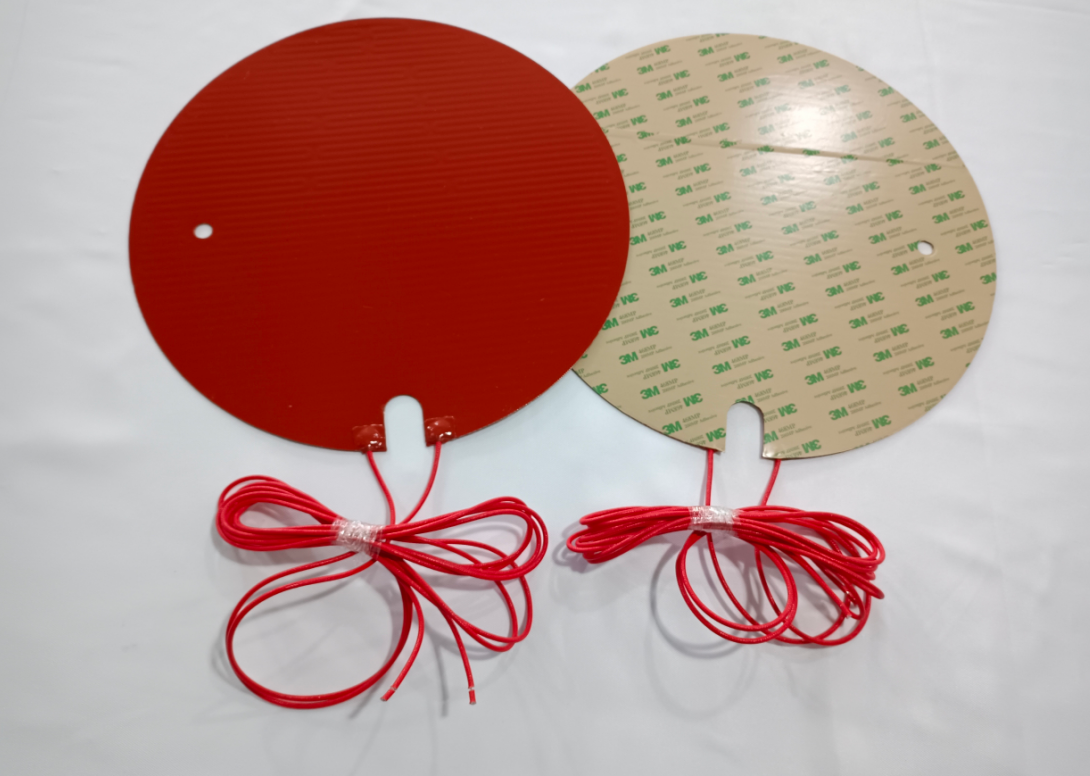

Silicone heaters can be customized to meet specific needs. Options include shaping the heater to fit curved or irregular surfaces, integrating thermostats or sensors for precise temperature control, and choosing secure bonding methods like vulcanization or adhesive-backed surfaces.

5. Advanced Heating Elements

The two primary heating technologies in silicone rubber heaters are etched foil and wire-wound elements. Etched foil heaters offer uniform heat distribution and fast response times, ideal for applications requiring precise temperature control, while wire-wound heaters are more robust for rugged use.

6. Easy Installation and Maintenance

Installing silicone heaters is straightforward, with options such as pressure-sensitive adhesives, factory bonding, or mechanical fasteners. Selecting the appropriate installation method ensures durability, optimal heat transfer, and extended service life.

7. Tailored for Specific Applications

Understanding the unique requirements of your application is critical. Silicone rubber heaters are used in a variety of ways—from preventing condensation in ATMs and vending machines to delivering precise temperature control in medical equipment and food service systems.

Silicone rubber heaters are versatile and reliable, but selecting the right design and working with a trusted supplier is key to ensuring your application’s success. Choose a vendor with expertise, attention to detail, and a commitment to delivering high-quality solutions on time.

By considering these factors, you can optimize the performance and longevity of your silicone rubber heater and ensure it meets your specific needs. If you have any questions when you chose a suitable heaters, please feel free to contact us at sales@hrx-heaters.com

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.