How PI Graphene Heating Films Achieve "Instant Heat-up" and "Ultra-Low Energy Consumption"?

12 Safety & Longevity Guidelines Before Installation for Flexible Film Heaters

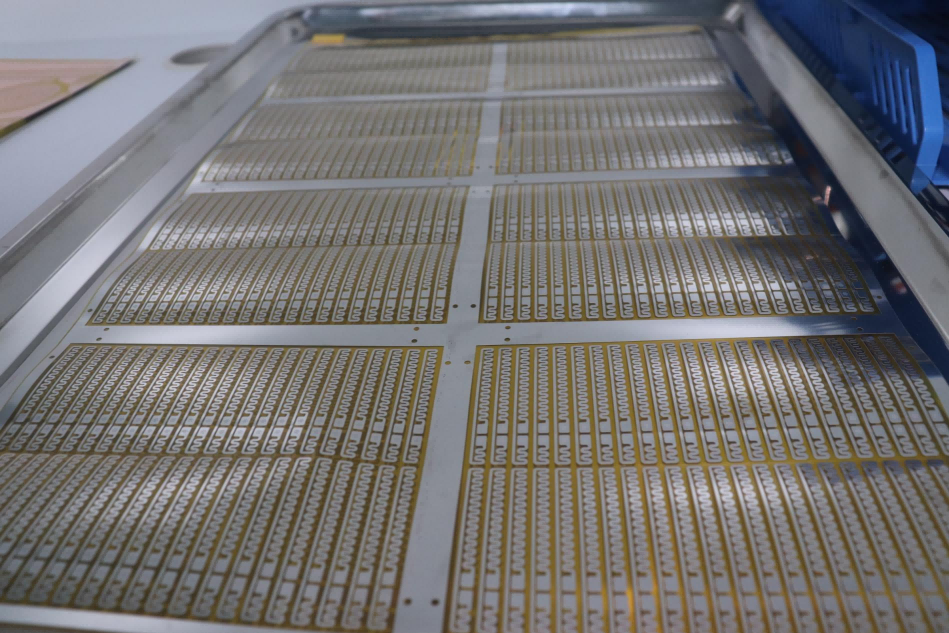

Battery Drying & Formation Equipment Heating Plate

How Flexible Heaters Achieve Consistent Medical Fluid Warming?

The Advantages of Polyimide Heaters in the Aerospace Industry

FeCrAl alloy, an industrially prevalent metal alloy composed primarily of iron (Fe), chromium (Cr), and aluminum (Al), has carved a niche for itself in the realm of electric heating applications. Its distinct properties, particularly its high electrical resistivity, allow it to generate substantial heat when an electric current is applied, making it a preferred material for electric heating elements. This blog delves into the unique characteristics of FeCrAl alloy, its operating principles, advantages, and limitations, as well as its widespread applications in various industries.

FeCrAl alloy is primarily valued for its ability to produce heat efficiently due to its high electrical resistivity. When a current passes through this alloy, it generates heat as a result of electrical resistance—a phenomenon known as the Joule effect. The resistance of the alloy causes the electrical energy to convert into thermal energy, making it an excellent conductor of heat while maintaining minimal current flow.

In addition to its thermal efficiency, FeCrAl alloy is known for its high melting point (approximately 1,400–1,500°C) and excellent stability at elevated temperatures. These features allow FeCrAl heating elements to operate reliably in high-temperature environments without compromising performance.

Key Properties of FeCrAl Alloy

1. High Electrical Resistivity: The high resistivity of FeCrAl alloy ensures that even a low current can generate substantial heat, making it energy-efficient and suitable for a variety of heating applications.

2. High Melting Point and Thermal Stability: With a melting point above 1,400°C, FeCrAl alloy can withstand extreme heat conditions, making it ideal for high-temperature heating elements used in industrial ovens, furnaces, and kilns.

3. Corrosion and Oxidation Resistance: The addition of chromium and aluminum gives the alloy a protective oxide layer, which enhances its resistance to corrosion and oxidation. This ensures that FeCrAl heating elements maintain their integrity even in harsh environments, prolonging their lifespan.

4. Durability and Longevity: Thanks to its excellent heat resistance and robust protective layer, FeCrAl alloy boasts a long service life, reducing maintenance and replacement costs for heating equipment.

Advantages of FeCrAl Alloy Heating Elements

1. Exceptional High-Temperature Performance: FeCrAl heating elements can consistently operate at temperatures up to 1,200°C, making them suitable for demanding industrial applications such as heat treatment, ceramics, and metal processing.

2. Energy Efficiency: The high resistivity of FeCrAl reduces the amount of current needed to achieve the desired heating level, leading to energy savings.

3. Corrosion and Oxidation Resistance: The aluminum oxide layer that forms on the surface of FeCrAl alloy acts as a protective barrier against oxidation and corrosion, extending the lifespan of the heating elements.

4. Cost-Effectiveness: Compared to other high-temperature heating materials like nickel-based alloys, FeCrAl is more affordable, making it a cost-efficient choice for large-scale industrial applications.

5. Durability: FeCrAl alloy's resistance to thermal fatigue and high thermal stability means it can withstand repeated heating and cooling cycles without degrading, ensuring longevity.

FeCrAl alloy heating elements are a cornerstone in the field of electric heating due to their excellent thermal efficiency, high-temperature performance, and durability. While they do have some limitations in extremely harsh environments, their overall benefits make them an ideal choice for a wide range of applications—from industrial furnaces to household appliances.

As industries continue to innovate and demand efficient heating solutions, FeCrAl alloy is likely to remain a key player in electric heating technologies. Its cost-effectiveness, combined with its robust thermal properties, ensures that it will continue to meet the evolving needs of various sectors.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.