Vulcanization Bonding for High-Performance Silicone Rubber Heaters

How Aluminium Foil Heaters Work and Where to Use Them?

How PI Graphene Heating Films Achieve "Instant Heat-up" and "Ultra-Low Energy Consumption"?

12 Safety & Longevity Guidelines Before Installation for Flexible Film Heaters

Battery Drying & Formation Equipment Heating Plate

In the realm of energy storage, lithium-ion batteries are the backbone of numerous applications, from electric vehicles to portable electronics and renewable energy systems. However, one of the most significant challenges these batteries face is their sensitivity to temperature variations. Of all the environmental factors that influence battery performance, temperature has the most profound impact on the charging and discharging capabilities of lithium-ion batteries. Understanding how low temperatures affect battery efficiency—and exploring solutions to mitigate these effects—are crucial for optimizing battery performance in cold climates.

Temperature directly affects the electrochemical reactions occurring at the electrode/electrolyte interface, which is often considered the "heart" of a battery. When temperatures drop, several adverse effects come into play:

1. Increased Electrolyte Viscosity: At low temperatures, the viscosity of the electrolyte increases, leading to reduced ionic conductivity. This slows down the movement of ions between the electrodes, which is vital for efficient charge and discharge cycles.

2. Reduced Electrochemical Activity: Low temperatures decrease the activity of the active materials within the battery, resulting in a higher concentration gradient of the electrolyte and increased polarization. This can cause charging to stop prematurely, preventing the battery from reaching its full capacity.

3. Lithium Plating on the Anode: One of the most critical issues is that at low temperatures, the diffusion rate of lithium ions into the carbon anode slows down significantly. As a result, lithium plating can occur, which not only reduces the battery's lifespan but can also lead to safety hazards, such as short circuits or thermal runaway.

4. Slower Reaction Kinetics: As temperatures decrease, the reaction rate at the electrodes drops. Even if the battery voltage remains constant, the discharge current is reduced, leading to a noticeable drop in the power output.

These challenges restrict the usability of lithium-ion batteries in cold environments, where efficient energy storage is essential. For example, electric vehicles operating in winter conditions or remote power systems exposed to freezing temperatures often experience significant drops in performance, resulting in shorter battery life and reduced reliability.

To counteract the adverse effects of cold temperatures, engineers have developed a practical yet effective solution: preheating. Preheating the battery before charging or use in low-temperature conditions has been shown to improve the battery's overall performance and extend its service life. By raising the temperature of the battery to an optimal level before operation, preheating can restore the electrochemical reaction rates, reduce polarization, and prevent lithium plating on the anode.

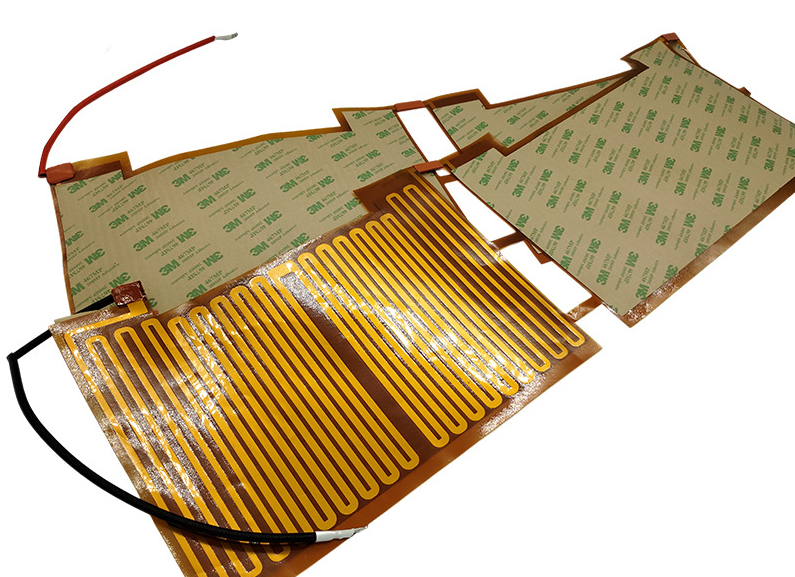

One of the most efficient methods for preheating lithium-ion batteries involves the use of flexible heaters. These heaters are thin, lightweight, and highly adaptable, making them ideal for integration into battery modules. Two of the most commonly used types of flexible heaters in battery applications are Polyimide (PI) heaters and Silicone heaters.

The application of flexible heaters for preheating lithium-ion batteries offers several advantages:

· Improved Low-Temperature Performance: By preheating the battery before use, flex heaters help restore optimal reaction rates and conductivity, significantly improving the battery's performance in cold environments.

· Extended Battery Life: Preventing lithium plating and reducing polarization through preheating helps prolong the lifespan of lithium-ion batteries, leading to lower maintenance costs and increased reliability.

· Increased Safety: Preheating ensures that the battery operates within a safe temperature range, reducing the risk of thermal runaway and other safety hazards associated with low-temperature operation.

· Enhanced Efficiency: By maintaining a stable operating temperature, preheating can enhance the overall energy efficiency of the battery, making it more suitable for demanding applications like electric vehicles, drones, and renewable energy storage.

As the world continues to transition toward electric mobility and renewable energy, the demand for efficient and reliable lithium-ion batteries will only increase. However, the limitations posed by cold temperatures remain a significant challenge. By integrating flexible heaters such as Polyimide and Silicone heaters into battery systems, manufacturers can enhance the performance, safety, and lifespan of lithium-ion batteries, particularly in cold climates.

Whether it's for electric vehicles navigating snowy roads or off-grid solar systems enduring harsh winters, preheating solutions are proving to be a game-changer in optimizing battery performance. As technological advancements continue, we can expect to see even more innovative solutions for overcoming the challenges of low-temperature environments, ensuring that lithium-ion batteries remain a viable energy storage solution for the future.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.