Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

Polyimide heaters are renowned for their exceptional thermal stability and flexibility, making them indispensable in a variety of industrial applications. A critical aspect of their performance, however, lies in the insulation of the weld points. Proper insulation is essential to ensure both the safety and efficiency of these heaters. In this blog, we’ll explore three common insulation methods, examining their advantages and disadvantages, to help you determine the best option for your specific needs.

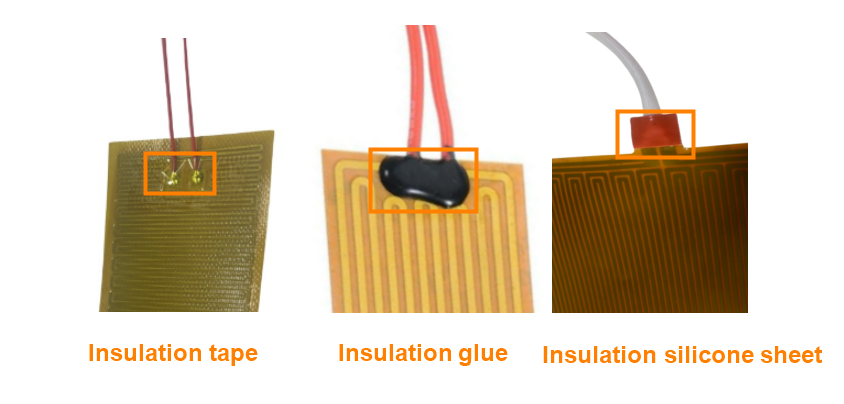

When it comes to insulating the weld points of polyimide heaters, there are three primary methods:

1. Insulation Polyimide Tape

2. Insulation Glue

3. Insulation Silicone Sheet

Each method offers unique benefits and drawbacks, which we will discuss in detail to guide you in making an informed decision.

Method 1: Insulation Tape

Advantages:

· Easy to Apply: Insulation tape is straightforward to use, making it easy to apply to weld points of various shapes and sizes. Its flexibility allows it to conform to different heater configurations.

· High Flexibility: Suitable for heaters of different sizes and shapes, the tape can be easily adapted to various designs.

· Cost-Effective: Both material and application costs are relatively low, making it an economical choice for many applications.

Disadvantages:

· Limited Durability: Over time, particularly in high-temperature environments, insulation tape may degrade, leading to potential issues like aging or detachment.

· Moderate Insulation Performance: While effective, the insulation provided by tape might not be as robust as other methods, especially in demanding conditions.

Method 2: Insulation Glue

Advantages:

· Convenient Application: Spot insulation glue is quick and easy to apply, requiring only a small amount of glue to effectively insulate the weld points. It also cures rapidly, speeding up the assembly process.

· High Versatility: Ideal for complex or irregularly shaped weld points, the glue can be applied precisely where needed.

Disadvantages:

· Poor Durability: In high-temperature environments or under mechanical stress, the glue may lose adhesion, leading to potential detachment and insulation failure.

· Average Insulation Performance: Compared to solid insulation materials, glue may not offer the same level of electrical insulation, making it less suitable for high-voltage applications.

Method 3: Insulation Silicone Sheets

Advantages:

· Superior Insulation Performance: Insulation sheets provide robust insulation protection, making them ideal for applications requiring high voltage resistance.

· High Temperature Resistance: Typically, these sheets are designed to withstand elevated temperatures, ensuring long-term durability in harsh environments.

Disadvantages:

· Increased Thickness: Insulation sheets are generally thicker than other methods, which can add to the overall dimensions of the heater assembly. This may be a drawback in applications with limited space.

· Complex Installation: Installing insulation sheets often requires precise alignment and securing, making the process more labor-intensive and time-consuming compared to other methods.

How to Choose the Right Insulation Method

Selecting the appropriate insulation method involves considering several factors, including the application environment, mechanical stress, design constraints, and ease of application.

· Application Environment: In high-temperature environments, insulation sheets or tapes that offer superior heat resistance are more suitable. Spot insulation glue may be sufficient for lower temperatures or less demanding applications.

· Mechanical Stress: For applications subject to significant vibration or mechanical stress, insulation sheets provide better durability and protection compared to glue.

· Design Constraints: If space is a concern, the thinner profile of insulation tape or glue may be more appropriate. However, if insulation performance is the top priority, the thickness of insulation sheets may be justified.

· Ease of Application: For quick and simple application, spot insulation glue is convenient, but for long-term reliability, especially in challenging environments, insulation tape or sheets may be more suitable.

Each insulation method has its own set of strengths and weaknesses, making them suitable for different scenarios. When choosing the right insulation method, it's important to consider the specific requirements of your application, such as temperature, mechanical stress, and space constraints. By selecting the most appropriate method, you can ensure that your polyimide heater operates safely and efficiently over its lifetime.

If you’re uncertain about which insulation method to choose, consulting with an expert can provide you with tailored advice. Remember, the right insulation not only protects your heater but also enhances its performance, making it a crucial decision in your overall design. If you don't require it, HRX heater is insulated with Silicone sheet.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.