Why High-Temperature 3D Printers Need Rogers Silicone Heaters

Choosing the Right Thermostat for Smart Temperature Control Needs

Silicone Rubber Heaters in Automotive: Durability Meets Innovation

Polyimide Heaters: Key Applications in the New Energy Industry

Why Mica Heater Need Multiple Through-Holes

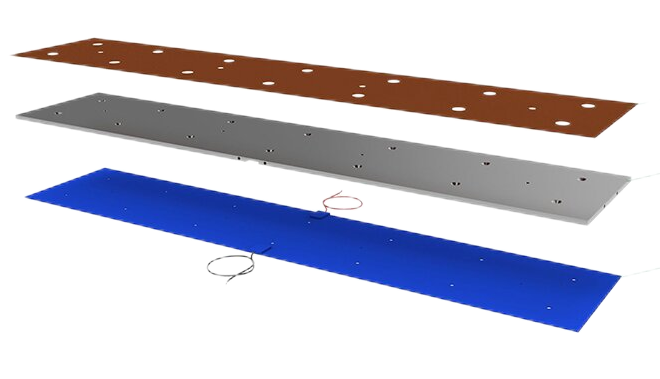

In dryer systems, whether for industrial or household applications, heating elements play a vital role in ensuring effective drying performance. With the need for efficient heat distribution and consistent temperature control, customized solutions have become increasingly popular. A standout combination in this regard is the use of aluminum plates paired with silicone heating sheets. These two materials, when customized to fit specific dryer requirements, provide an excellent balance of performance, durability, and energy efficiency. In this blog, we explore the advantages of using customized aluminum plates and silicone heating sheets in dryer applications and how they contribute to better heating efficiency.

Aluminum is one of the most widely used materials in heating systems due to its remarkable properties. Its lightweight nature makes it easy to integrate into various systems without adding significant bulk. More importantly, aluminum is known for its excellent thermal conductivity, which means it can quickly and evenly distribute heat across its surface. In the context of dryer systems, this uniform heat distribution is crucial for ensuring that the drying process is efficient and even, preventing hot spots or under-heated areas that could affect product quality.

In industrial and household dryers alike, aluminum plates are often chosen for their durability and corrosion resistance, which ensures long-lasting performance even in demanding environments. Whether it's drying clothes, food products, or industrial components, aluminum plates help optimize heat transfer, leading to faster drying times and lower energy consumption.

While aluminum plates handle heat distribution, the silicone heating sheets are responsible for generating the heat itself. Silicone, as a material, offers incredible flexibility and durability. Its high-temperature resistance allows it to withstand prolonged heating cycles without degrading, making it an ideal choice for demanding dryer applications.

One of the key advantages of silicone heating sheets is their ability to provide uniform heating. The silicone material ensures even heat generation across the surface, which, when paired with the conductive aluminum plate, creates an efficient heating system. Moreover, silicone heating sheets can be tailored to meet specific voltage and wattage requirements, making them highly versatile for a wide range of dryer applications.

Off-the-shelf solutions may not always meet the unique requirements of different dryer systems. This is where customized aluminum plates and silicone heating sheets come into play. Customization allows for the heating elements to be specifically designed in terms of size, shape, wattage, and power density to fit the precise needs of a dryer system.

For example, dryers used in the food industry may require precise temperature control to avoid damaging sensitive products. By customizing the aluminum plate and silicone heating sheet, manufacturers can achieve optimal drying conditions tailored to their specific processes. Additionally, customization can enhance energy efficiency by ensuring that the heating elements match the dryer’s operational specifications, avoiding over- or under-heating.

Industries that benefit from these customized solutions include food processing, textiles, and electronics, where consistent drying is critical to maintaining product quality.

When designing customized heating elements for dryer systems, several factors must be considered. First, the heating power needs to match the dryer’s requirements to avoid energy waste or insufficient heating. The compatibility between the aluminum plate and silicone heating sheet must also be considered to ensure they work harmoniously to provide efficient heating.

Temperature control is another critical factor, as the dryer system must maintain a consistent temperature to ensure uniform drying. The thickness and shape of the aluminum plate can be tailored to suit the physical space within the dryer, allowing for more effective heat distribution.

Safety is also a significant concern when customizing heating elements. High-quality silicone heating sheets are designed to operate at high temperatures while maintaining electrical insulation, ensuring both performance and safety.

Conclusion

The combination of customized aluminum plates and silicone heating sheets provides an ideal heating solution for dryer systems. The lightweight, thermally conductive properties of aluminum, combined with the uniform heating capabilities and flexibility of silicone, offer superior performance and durability. By opting for customized heating elements, manufacturers can achieve enhanced energy efficiency, precise temperature control, and improved product quality.

As dryer technology evolves, the demand for more efficient and reliable heating systems will continue to grow. Whether you're working in the food processing, textile, or electronics industry, customized aluminum plates and silicone heating sheets can be tailored to meet your specific needs. If you're looking to improve your dryer system's performance, contact us today for customized heating solutions designed to enhance your operation.

Related product links

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.