Polyimide heaters, known for their flexibility, durability, and efficient thermal performance, are integral in various industrial and consumer applications. A critical component of these heaters is the conductor, which plays a vital role in determining the heater's performance, efficiency, and application suitability. In this blog, we will explore the different conductor options available for polyimide heaters and discuss their unique characteristics.

1. Red copper. Red copper, also known as industrial pure copper, derives its name from its distinctive rose-red color. When exposed to air, it forms a purple oxide film on its surface. Red copper is valued for its exceptional electrical conductivity, thermal conductivity, ductility, and corrosion resistance. It exhibits excellent plasticity, making it easy to shape and form. However, it tends to have relatively lower strength and hardness compared to other alloys.

2. Brass. H65 brass, also referred to as a copper-zinc alloy, typically contains 64-68% copper. It is renowned for its excellent mechanical properties, including good hot and cold plasticity, which facilitate ease of machining. H65 brass is known for its favorable brazing and welding properties, as well as its corrosion resistance.

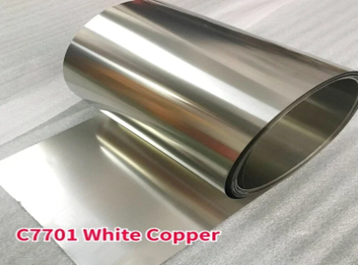

3. White copper. White copper C7701, also known by the Chinese standard BZN18-26, is an alloy composed of copper, nickel, and zinc. It exhibits a silver-white metallic luster, earning its name "white copper". This alloy is prized for its excellent cold workability and ductility, along with corrosion resistance and fatigue resistance. It offers good formability and weldability, complemented by favorable electrical properties, mechanical strength, and radiation shielding performance.

4. 304 stainless steel. Commonly known in the industry as 18/8 stainless steel, contains more than 18% chromium and more than 8% nickel. It is resistant to high temperatures up to 800℃ and offers excellent processing performance, high toughness, and strong corrosion resistance.

5. Iron chromium aluminum. The ferrite alloy composed of iron, chromium, and aluminum, commonly specified as 1Cr13Al4, is designed for flexible heaters. At high temperatures, it forms a dense, adhesive anodic coating that provides excellent oxidation resistance. The alloy also offers good resistance to cementation, sulfur contamination, and corrosion, along with high resistivity and a low temperature coefficient of resistance.

6. Nickel-chromium alloy. The nickel-chromium alloy commonly known as Cr20Ni80 is a resistance electric heating alloy. This alloy is known for its stable structure and consistent electrical and physical properties. It exhibits good mechanical properties at high temperatures, including excellent cold deformation plasticity. Cr20Ni80 also offers good weldability and does not develop brittle fractures with prolonged use.

The selection of the conductor material in kapton heaters largely depends on the specific application requirements, including environmental conditions, cost constraints, and performance needs. Here are some considerations from HRX Heaters to help guide the choice:

Application Environment: For harsh environments, materials like nickel or nickel-chromium are preferred due to their corrosion resistance.

Performance Requirements: For applications demanding high thermal efficiency, silver or copper might be ideal due to their superior conductivity.

Budget Constraints: Cost-effective solutions often involve copper, whereas premium applications might justify the use of gold or silver.

Design Complexity: Malleable materials like copper are better suited for intricate heater designs requiring flexibility.

By understanding the unique properties of each conductor material, engineers and designers can make informed decisions to optimize the performance and longevity of PI heaters in their specific applications. If there is any question with the choice of conductor, please contact us at sales@hrx-heaters.com.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.