Vulcanization Bonding for High-Performance Silicone Rubber Heaters

How Aluminium Foil Heaters Work and Where to Use Them?

How PI Graphene Heating Films Achieve "Instant Heat-up" and "Ultra-Low Energy Consumption"?

12 Safety & Longevity Guidelines Before Installation for Flexible Film Heaters

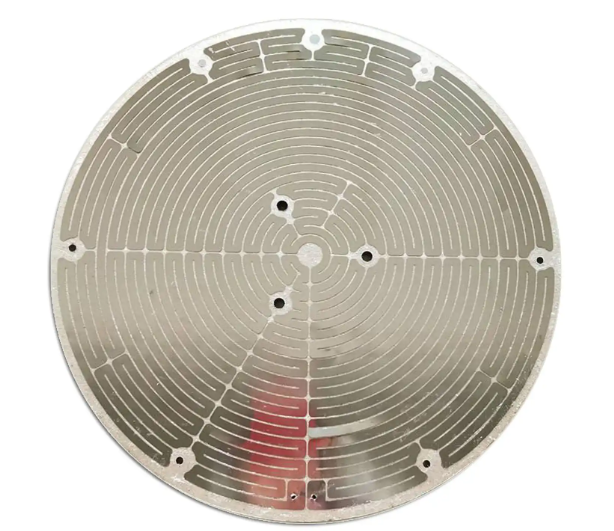

Battery Drying & Formation Equipment Heating Plate

Mica heating sheets are widely used in various industries due to their excellent insulation, thermal resistance, and high-voltage performance. However, a common phenomenon observed during the first use of mica heating sheets is the emission of smoke. This often raises concerns about product quality and safety. Here, we explore the reasons behind this occurrence and why it is considered normal and environmentally friendly.

The smoke emitted when mica heating sheets are used for the first time is a result of the heating process interacting with trace residues left over from production. These residues include:

1. Water Content:

Mica naturally contains a small amount of water. During manufacturing, even after processing, trace moisture can remain trapped within the mica structure.

2. Small Molecules in the Binder:

The adhesive used in assembling mica heating sheets may contain tiny molecular residues. These molecules can vaporize when exposed to high temperatures.

3. Chemical Solvents:

Traces of solvents used during the production process may also linger in the material. When the mica heating sheet is first heated, these solvents evaporate, contributing to the visible smoke.

Mica heating sheets are primarily made from mica flakes, which are naturally occurring mineral composites. The main components include:

· Polysilica Mica: Known for its high silicon content, polysilica mica provides excellent thermal and electrical insulation.

· Quartz, Garnet, and Rutile: These minerals enhance the structural integrity of the sheet. Garnet, in particular, is rich in iron (Fe) and magnesium (Mg), which contribute to its durability.

· Sodium Feldspar, Vermiculite, and Chlorite: These minerals may also appear in mica, depending on its natural source.

Mica heating sheets are often referred to as "good black bodies" due to their effective heat absorption and low thermal loss, making them highly efficient for heating applications.

When the mica heating sheet is powered on for the first time, the heat causes any remaining water, small molecular residues, and chemical solvents to evaporate. This leads to the release of a small amount of smoke, which is visible for a short period.

This phenomenon is completely normal and typically subsides after the initial use. It does not indicate a defect in the product or pose any significant safety risks. The amount of smoke is often minimal and varies depending on the specific production process and the materials used.

Despite the initial smoke emission, mica heating sheets are considered one of the most environmentally friendly heating elements available. The materials used are natural, and the smoke produced is non-toxic, comprising only trace residues from the manufacturing process. After the initial burn-off, the mica heating sheet operates cleanly and efficiently, making it a sustainable choice for heating applications.

The emission of smoke during the first use of a mica heaters is a normal and harmless occurrence. It results from the evaporation of residual water, small molecules in the binder, and traces of solvents from production. Understanding this phenomenon can help users feel confident in the safety and reliability of mica heating sheets, which remain a popular and eco-friendly heating solution in various industries.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.