Vulcanization Bonding for High-Performance Silicone Rubber Heaters

How Aluminium Foil Heaters Work and Where to Use Them?

How PI Graphene Heating Films Achieve "Instant Heat-up" and "Ultra-Low Energy Consumption"?

12 Safety & Longevity Guidelines Before Installation for Flexible Film Heaters

Battery Drying & Formation Equipment Heating Plate

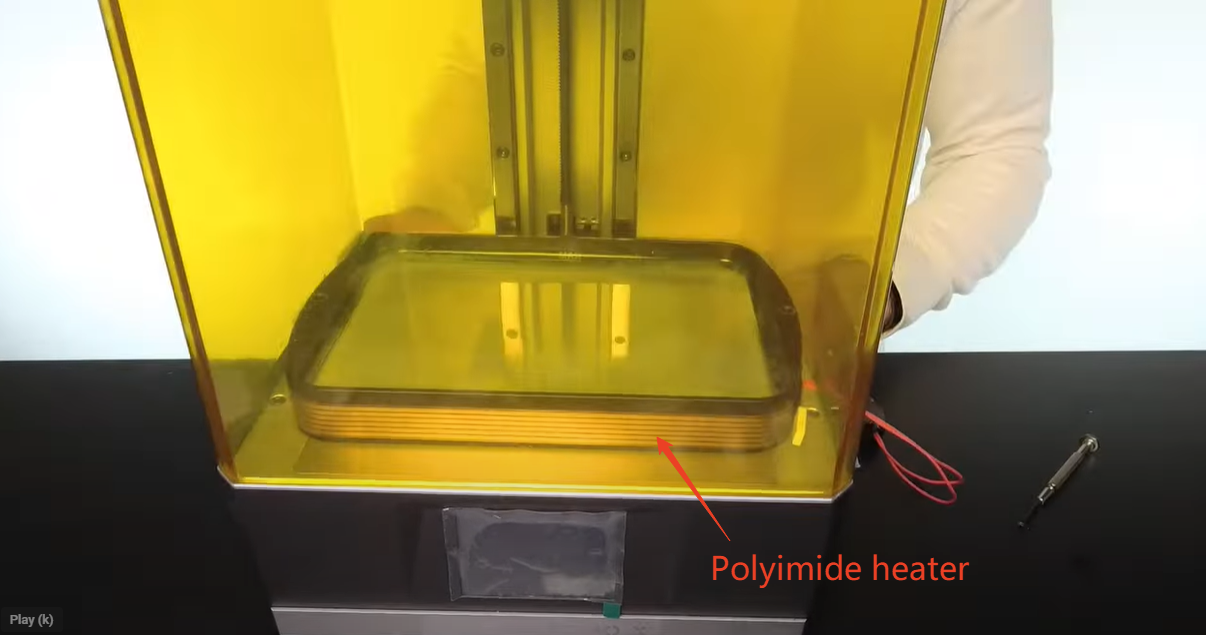

The demand for high-precision 3D printing has surged across industries, with resin printers gaining popularity for their ability to produce detailed and complex parts. One area ripe for innovation is the integration of heating solutions to optimize resin curing and improve print quality. In this blog, we explore the benefits of embedding Polyimide heaters around the transparent build platform edges of a 3D resin printer.

Resin printing relies on photopolymerization, a process where liquid resin is hardened layer by layer using UV light. Maintaining an optimal resin temperature is crucial for several reasons:

1. Improved Resin Flow: Resins become less viscous at elevated temperatures, allowing for smoother flow and reducing air bubble formation during printing.

2. Faster Curing Times: Warmer resin cures more efficiently under UV light, enhancing print speed.

3. Consistent Results: Controlled heating ensures uniform curing across layers, reducing warping or unevenness in the final print.

Polyimide heaters are thin, lightweight, and flexible, making them ideal for integration into delicate systems like 3D resin printers. Here’s why they are a great choice for heating the edges of the transparent build platform:

1. Uniform Heat Distribution: Polyimide heaters provide consistent heat across their surface, ensuring the resin temperature is evenly maintained.

2. Compact Design: Their slim profile allows them to be discreetly embedded along the build platform’s edges without obstructing the printing process or visibility.

3. Durability: Resistant to high temperatures and chemical exposure, Polyimide heaters can withstand the challenging environment of a 3D printer.

4. Energy Efficiency: These heaters are designed to consume minimal energy while delivering reliable performance.

When integrating Polyimide heaters into a 3D resin printer, consider the following design aspects:

Temperature Control System: Pair the heaters with a precise temperature control system to maintain resin temperatures within the recommended range (typically 25–30°C).

Placement Strategy: Position the heaters along the transparent platform’s edges to avoid interference with UV light exposure while ensuring optimal heating.

Power Requirements: Ensure the printer’s power supply can support the additional load without compromising overall performance.

1. Enhanced Print Quality: Consistent resin temperature minimizes defects, leading to higher-quality prints.

2. Increased Reliability: Reduced risk of failed prints due to temperature fluctuations.

3. Broader Material Compatibility: Certain specialty resins perform better at specific temperatures, expanding the range of usable materials.

4. Improved Productivity: Faster curing and reduced print defects translate to quicker turnaround times.

Integrating Polyimide heaters into the transparent build platforms of 3D resin printers is a game-changer for the industry. This simple yet effective innovation enhances print quality, reliability, and material versatility, making it a valuable addition for both industrial and consumer-grade resin printers. As the 3D printing landscape evolves, such advancements underscore the importance of thermal management in achieving next-level precision and performance.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.