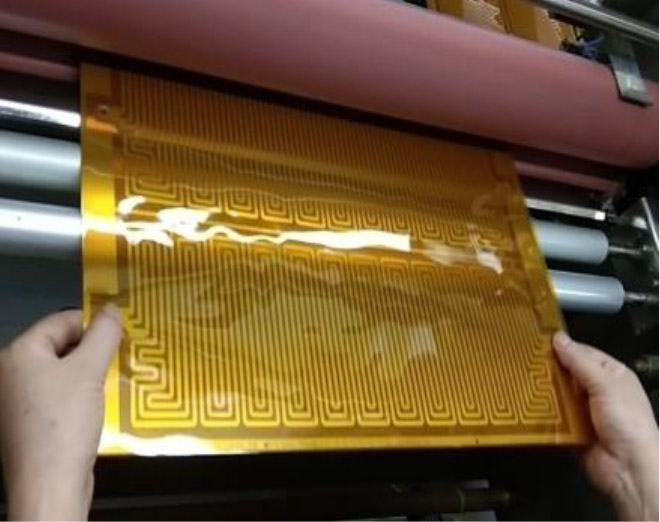

In the world of flexible heating elements, polyimide (PI) film stands out for its excellent thermal and electrical insulation properties, along with its lightweight, flexible form factor. PI film heaters are frequently used in fields where reliable, consistent heating is critical. However, not all PI films are created equal, and the choice between cold-pressed and hot-pressed PI film can significantly impact performance and longevity. Here, we explore the differences in manufacturing, performance, and why HRX Heater relies on hot-pressed PI film as the default process to deliver a reliable, high-performance product.

The primary difference between cold-pressed and hot-pressed PI film heaters lies in how they are manufactured:

Cold-Pressed PI Film Heaters: This process involves layering PI film with adhesive to bond them together. No additional high temperatures or pressures are applied, which makes the manufacturing process simpler and more cost-effective. However, the use of adhesives to bond the layers together can introduce structural limitations, such as air pockets, which may impact the heater’s long-term reliability.

Hot-Pressed PI Film Heaters: In the hot-pressing process, the PI layers are bonded using high temperatures (over 200°C) and substantial pressure (approximately 200 tons) for an extended period. This process creates a much stronger molecular bond without the need for adhesives, resulting in a compact, high-integrity structure that is well-suited for more rigorous applications.

The choice of manufacturing process has a direct impact on the performance and resilience of the heating element:

Air Pocket and Oxidation Resistance: Cold-pressed PI film, due to its adhesive-based bonding, is prone to forming small air pockets within the layers. These pockets can lead to oxidation over time, increasing the risk of rust, delamination, and premature failure in humid or corrosive environments. This makes cold-pressed PI film less suitable for applications requiring high reliability.

Hot-pressed PI film eliminates this issue by using heat and pressure to form a tight, air-free bond. Without air pockets, the risk of oxidation is greatly reduced, resulting in a heating element that can perform reliably in harsh environments without structural degradation over time.

Temperature Resistance: The adhesive used in cold-pressed PI film heaters often limits their temperature tolerance. Adhesives may weaken at higher temperatures, leading to separation between layers and limiting their suitability for high-temperature applications.

In contrast, hot-pressed PI films do not rely on adhesives and can tolerate extreme temperatures without degradation. This makes hot-pressed PI heaters the preferred choice for applications that involve sustained or fluctuating high temperatures, such as industrial machinery, medical devices, and automotive systems.

Structural Integrity and Long-Term Stability: Cold-pressed PI films are more likely to delaminate or peel over time, especially when exposed to repetitive thermal cycling. This can result in unreliable performance and higher maintenance costs.

Hot-pressed PI films are exceptionally stable. The intense heat and pressure bonding process creates a robust structure that is highly resistant to delamination. This longevity makes hot-pressed PI heaters ideal for applications where long-term reliability is essential.

Given these critical performance differences, HRX Heater uses hot-pressed PI film as the default manufacturing process for all its PI film heaters. By leveraging hot-pressed PI film, HRX ensures that its heating solutions are capable of meeting the rigorous demands of high-performance applications. This choice brings multiple benefits to HRX Heater customers:

Enhanced Durability and Reliability: Hot-pressed PI film provides unparalleled stability, even under high temperatures and adverse environmental conditions, ensuring that HRX Heater products offer consistent performance over extended periods.

Oxidation and Rust Prevention: The air-tight structure of hot-pressed PI film mitigates oxidation risks, eliminating concerns about rust, delamination, or layer separation over time. This is especially beneficial for applications that involve exposure to moisture, such as in outdoor or industrial environments.

Cost-Effectiveness in the Long Run: Although the initial cost of hot-pressed PI heaters may be higher than cold-pressed options, their longevity and durability minimize the need for replacements or maintenance, making them a cost-effective solution over the long term.

The choice between cold-pressed and hot-pressed PI film is not merely about cost—it’s about meeting the specific demands of an application with the right technology. While cold-pressed PI film heaters may be adequate for low-stress, low-cost applications, hot-pressed PI film heaters provide a superior, robust option for high-performance needs. HRX Heater’s commitment to quality is reflected in its use of hot-pressed PI film as the default, ensuring its products deliver durability, reliability, and value to customers in critical industries.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.